Uploaded by

tonaker796

Buckling of Thin Structures: Analytical & Numerical Studies

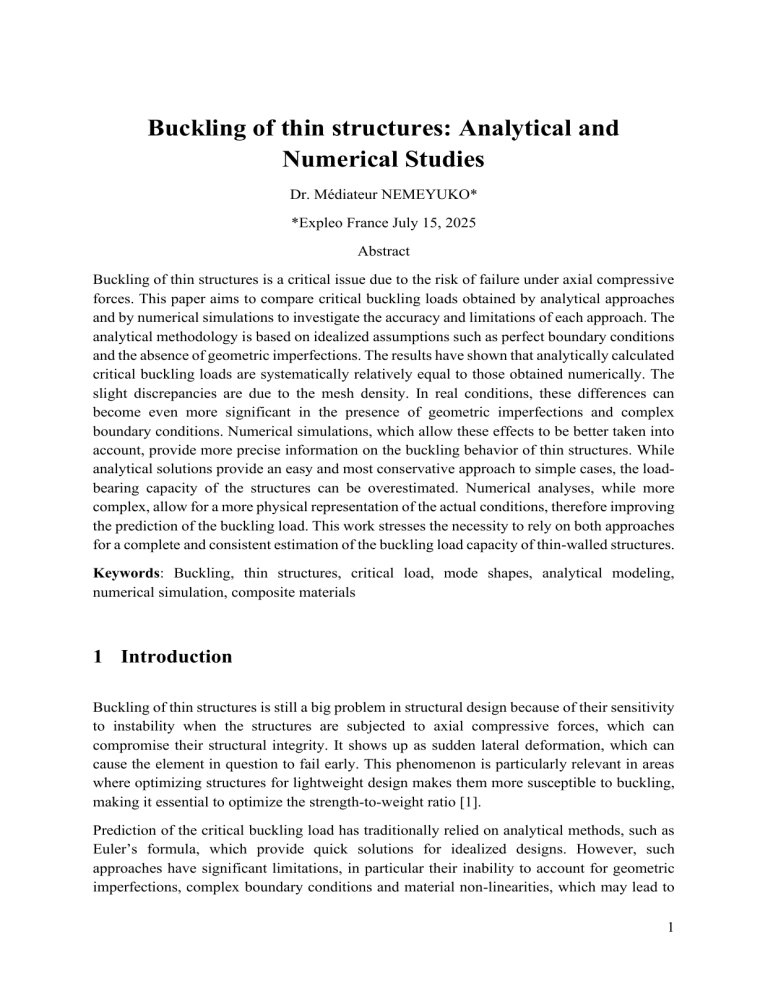

Buckling of thin structures: Analytical and Numerical Studies Dr. Médiateur NEMEYUKO* *Expleo France July 15, 2025 Abstract Buckling of thin structures is a critical issue due to the risk of failure under axial compressive forces. This paper aims to compare critical buckling loads obtained by analytical approaches and by numerical simulations to investigate the accuracy and limitations of each approach. The analytical methodology is based on idealized assumptions such as perfect boundary conditions and the absence of geometric imperfections. The results have shown that analytically calculated critical buckling loads are systematically relatively equal to those obtained numerically. The slight discrepancies are due to the mesh density. In real conditions, these differences can become even more significant in the presence of geometric imperfections and complex boundary conditions. Numerical simulations, which allow these effects to be better taken into account, provide more precise information on the buckling behavior of thin structures. While analytical solutions provide an easy and most conservative approach to simple cases, the loadbearing capacity of the structures can be overestimated. Numerical analyses, while more complex, allow for a more physical representation of the actual conditions, therefore improving the prediction of the buckling load. This work stresses the necessity to rely on both approaches for a complete and consistent estimation of the buckling load capacity of thin-walled structures. Keywords: Buckling, thin structures, critical load, mode shapes, analytical modeling, numerical simulation, composite materials 1 Introduction Buckling of thin structures is still a big problem in structural design because of their sensitivity to instability when the structures are subjected to axial compressive forces, which can compromise their structural integrity. It shows up as sudden lateral deformation, which can cause the element in question to fail early. This phenomenon is particularly relevant in areas where optimizing structures for lightweight design makes them more susceptible to buckling, making it essential to optimize the strength-to-weight ratio [1]. Prediction of the critical buckling load has traditionally relied on analytical methods, such as Euler’s formula, which provide quick solutions for idealized designs. However, such approaches have significant limitations, in particular their inability to account for geometric imperfections, complex boundary conditions and material non-linearities, which may lead to 1 an overestimation of the actual load-bearing capacity of thin structures. In addition, Springhetti et al. showed that analytical methods may not accurately capture the post-buckling behavior of thin cylindrical shells [2]. Conversely, numerical simulations allow more realistic conditions to be modeled but they require significant computational resources to ensure accurate results. Bin Kamarudin et al. have used the finite element method to analyze the buckling of thin composite structures, highlighting the influence of geometric parameters and boundary conditions on the critical load [3]. This study aims to compare the critical buckling loads obtained by analytical and numerical methods for thin structures. The aim is to assess the accuracy and limitations of each approach, identify differences between the results and analyze the factors influencing these differences. This comparison should lead to a better understanding of the conditions of application of each method and provide recommendations for a more reliable assessment of the risk of buckling in the design of thin structures. 2 Analytical modeling 2.1 Buckling of a simply supported rectangular plate, uniformly compressed in one direction The forces, uniformly distributed along the edges, are characterized by an intensity per unit length, denoted 𝑁𝑥 . By progressively increasing the magnitude of 𝑁𝑥 , a critical threshold is reached, beyond which the flat, stable configuration of the plate becomes unstable, leading to buckling, as shown in figure 1. This threshold is called the critical buckling load. Figure 1: Plate under compression in the same direction. For a plate with simply supported boundary conditions, the deflection 𝑤(𝑥, 𝑦) can be expressed as a double series: 2 ∞ ∞ 𝑚𝜋𝑥 𝑛𝜋𝑦 ) sin ( ) 𝑎 𝑏 (1) 𝑤(𝑥, 𝑦) = ∑ ∑ 𝑎𝑚𝑛 sin ( 𝑚=1 𝑛=1 where 𝑚 and 𝑛 represent the buckling modes in the 𝑥 and 𝑦 directions, respectively. Experimental and numerical studies have confirmed that these theoretical approaches can reliably estimate the critical load, even for composite plates or plates with small initial imperfections [4] [5]. In this case, the bending strain energy of a compressed plate can be expressed as follows: ∞ ∞ 2 𝜋 4 𝑎𝑏 𝑚 2 𝑛2 2 ∆= 𝐷 ∑ ∑ 𝑎𝑚𝑛 ( 2 + 2) 8 𝑎 𝑏 (2) 𝑚=1 𝑛=1 where 𝐷 is the bending stiffness of the plate, 𝑎𝑚𝑛 are the coefficients of the buckling modes, and m, 𝑛 are the indices representing the modes in the 𝑥 and 𝑦 directions. The work done by compressive forces during buckling can be calculated as a function of displacements in the mid-plane of the plate. For a uniform force 𝑁𝑥 in the 𝑥 direction, the expression becomes: 1 𝜕𝑤 2 𝜕𝑤 2 𝜕2𝑤 ∆𝑇 = − ∬ [𝑁𝑥 ( ) + 𝑁𝑦 ( ) + 2𝑁𝑥𝑦 2 ] 𝑑𝑥𝑑𝑦 2 𝜕𝑥 𝜕𝑦 𝜕𝑥 (3) In the case of a simply supported plate, 𝑁𝑦 and 𝑁𝑥𝑦 can be neglected. The integral is then reduced to: ∞ ∞ 2 𝑎 𝑏 1 𝜕𝑤 2 𝜋 4 𝑎𝑏 𝑚 2 𝑛2 2 ∆𝑇 = 𝑁𝑥 ∫ ∫ ( ) 𝑑𝑥𝑑𝑦 = 𝐷 ∑ ∑ 𝑎𝑚𝑛 ( 2 + 2) 2 𝜕𝑥 8 𝑎 𝑏 0 0 (4) 𝑚=1 𝑛=1 By balancing the bending strain energy ∆ from equation (2) and the work of the compressive forces ∆𝑇 from equation (4), the critical load 𝑁𝑥 is obtained as follows: ∞ ∞ ∞ ∞ 2 𝜋2𝑏 𝜋 4 𝑎𝑏 𝑚 2 𝑛2 2 2 2 𝑁 ∑ ∑ 𝑚 𝑎𝑚𝑛 = 𝐷 ∑ ∑ 𝑎𝑚𝑛 ( 2 + 2 ) 8𝑎 𝑥 8 𝑎 𝑏 𝑚=1 𝑛=1 (5) 𝑚=1 𝑛=1 We can isolate 𝑁𝑥 in order to obtain: 2 𝑚 2 𝑛2 ∞ ∞ 2 𝑎 𝜋 𝐷 ∑𝑚=1 ∑𝑛=1 𝑎𝑚𝑛 ( 2 + 2 ) 2 2 𝑁𝑥 = 𝑎 ∞ 2 𝑎2 ∑∞ ∑ 𝑚 𝑚𝑛 𝑚=1 𝑛=1 𝑏 (6) This relationship provides a formulation for the critical load in terms of the geometric and mechanical properties of the plate and its boundary conditions. Expression (15) will be maximized, when all values of coefficients 𝑎𝑚𝑛 = 0, except 1. This allows us to state: 3 This relationship can be used to determine the critical load as a function of the geometric and mechanical properties of the plate, as well as the boundary conditions. The expression (6) is maximal when all coefficients 𝑎𝑚𝑛 , except 1, are equal to zero. Consequently, we obtain: 2 𝑎 2 𝜋 2 𝐷 𝑚 2 𝑛2 𝑁𝑥 = ( 2 + 2) 𝑚2 𝑎 𝑏 (7) To minimize the buckling load 𝑁𝑥 , it is important to consider buckling modes where the number of waves in each direction is optimized. Physically, the critical configuration corresponds to the mode where a single half-wave is formed in the direction perpendicular to the compression (𝑛 = 1), while there may be several half-waves (𝑚) in the compression direction. This condition reflects the most likely instability of the plate under compression. By substituting 𝑛 = 1 in the general expression (7), the critical buckling load becomes: 2 𝜋2𝐷 1 𝑛2 (𝑁𝑥 )𝑐𝑟 = 2 (𝑚 + ) 𝑎 𝑚 𝑏2 (8) To simplify matters further, this expression can be rewritten as follows: (𝑁𝑥 )𝑐𝑟 = 𝜋 2 𝐷 𝑚𝑏 𝑎 2 ( + ) 𝑏2 𝑎 𝑏 (9) These two forms, given respectively by the equations (8) and (9), are equivalent and allow us to analyze the critical load as a function of the geometric dimensions a and b, as well as of the mode 𝑚. The critical load is minimized for an optimum value of m, which depends on the ratio of the dimensions a/b. This means that, for rectangular plates, the buckling configuration is often dominated by the geometry and mechanical properties of the plate. In real-world applications, such as structural panels in aeronautics or civil engineering, this expression is used to determine the permissible critical load to avoid buckling. Furthermore, it has been shown that for simply supported isotropic plates, analytical solutions correspond well to experimental measurements [5] [6]. The amplitude of the second factor in the expression (8) depends strongly on the geometric ratio a/b and the mode m, which represents the number of half-waves in the compression direction. If 𝑎 < 𝑏, the second term in brackets in the expression (8) is always less than the first. In this case, the minimum value of the critical load is obtained for 𝑚 = 1, indicating that the plate deforms in a single half-wave in the compression direction. The corresponding deflection surface can be represented as follows: 𝑤 = 𝑎11 sin 𝜋𝑥 𝜋𝑦 𝑎 𝑏 (10) 4 The maximum deflection 𝑎11 remains undefined in this analysis as long as we assume that the deformations are small enough to neglect the extension of the mid-plane of the plate. By substituting 𝑚 = 1 in the expression (9), the critical load takes the form: (𝑁𝑥 )𝑐𝑟 = 𝜋2𝐷 𝑏 𝑎 2 ( + ) 𝑏2 𝑎 𝑏 (11) By keeping the plate width 𝑏 constant while gradually changing the length 𝑎, the factor before the brackets in the expression (11) remains constant, while the factor between the brackets changes with the ratio 𝑎/𝑏. When 𝑎 = 𝑏, the value of this factor becomes minimal, indicating that for a given plate width, the critical load is lowest when the plate is square. In this case, th e expression of the critical load is simplified: (𝑁𝑥 )𝑐𝑟 = 4𝜋 2 𝐷 𝑏2 (12) For different plate proportions, the expression (12) can be generalized as [7]: (𝑁𝑥 )𝑐𝑟 = 𝑘 𝜋2𝐷 𝑏2 (13) where 𝑘 is a numerical factor depending on the ratio 𝑎/𝑏. Now let’s assume that the plate deforms in two half-waves (𝑚 = 2) in the compression direction. The corresponding deflection surface is: 𝑤 = 𝑎21 sin 2𝜋𝑥 𝜋𝑦 sin 𝑎 𝑏 (14) This implies the use of a bending line dividing the plate into two halves, each half being equivalent to a simply supported plate of length 𝑎/2. In this case, we can use the expression (11) to calculate the critical load, but replace a with 𝑎/2, which gives: (𝑁𝑥 )𝑐𝑟 = 𝜋 2 𝐷 2𝑏 𝑎 2 ( + ) 𝑏 2 𝑎 2𝑏 (15) Transitions between buckling modes (𝑚 and 𝑚 + 1) occur when two corresponding curves have the same ordinate, as shown in figure 7. This condition can be expressed by the following equation: (𝑚 + 1)𝑏 𝑚𝑏 𝑎 𝑎 + = + (𝑚 + 1)𝑏 𝑎 𝑚𝑏 𝑎 (16) We get the critical relationship between 𝑎/𝑏 and 𝑚 : 𝑎 = √𝑚(𝑚 + 1) 𝑏 (17) 5 Thus, the number of half-waves 𝑚 increases with the ratio 𝑎/𝑏. For very long plates (𝑎/𝑏 ≫ 1), 𝑚 becomes large and the equation (17) can be approximated by: 𝑎 ≈𝑚 𝑏 (18) This means that a very long plate will buckle into several half-waves, each with a length close to the width b. In this way, the plate is roughly divided into squares. Once 𝑚 has been determined from figure 7 or equation (31), the critical load can be calculated from expression (17) by substituting the length of a half-wave 𝑎/𝑚 for 𝑎 : 2 𝜋2𝐷 1 (𝑁𝑥 )𝑐𝑟 = 2 ( + 𝑚) 𝑏 𝑚 (19) For varying values of the a/b ratio, the coefficient k remains constant for a given mode m. Consider a short rectangular plate, simply supported, with the following properties: - 𝐸 = 220 GPa = 220 × 103 MPa, where 𝐸 is the modulus of elasticity (or Young’s modulus) of the material. 𝜈 = 0.3, where 𝜈 is Poisson’s ratio, a unitless constant describing the relationship between longitudinal and transverse deformations. 𝑏/ℎ = 100, where ℎ is the plate thickness, in mm. 𝑏 = 100 mm. The flexural rigidity D is a fundamental mechanical property used in plate stability analysis. It appears in the critical buckling load formula and depends on the elastic properties of the material and the plate geometry. The formula for D is given by: 𝐸ℎ3 𝐷= 12(1 − 𝜈 2 ) (20) where 1 − 𝜈 2 is the correction factor to account for the isotropic nature of the material. The flexural rigidity 𝐷 directly influences a plate’s ability to resist buckling forces. The higher 𝐷, the stiffer the plate and the higher the critical buckling load. A low thickness ℎ significantly reduces 𝐷, which in turn reduces the plate’s ability to resist buckling. Low Poisson’s ratio materials (𝜈) have slightly higher stiffness for the same thickness. The critical load (𝑁𝑥 )𝑐𝑟 is calculated for different values of a/b, and the results are presented in table 1. Its evolution as a function of a/b for 𝑚 = 1 is shown in figure 2. 𝑎/𝑏 𝑘 (𝑁𝑥 )𝑐𝑟 𝑎/𝑏 𝑘 (𝑁𝑥 )𝑐𝑟 0.2 27.04 537.11 1.2 4.13 82.12 0.3 0.4 0.5 0.6 0.7 0.8 13.20 8.41 6.25 5.14 4.53 4.20 262.22 167.05 124.45 102.05 89.99 83.47 1.3 1.4 1.5 1.6 1.7 1.8 4.28 4.47 4.69 4.95 5.23 5.54 85.05 88.79 93.25 98.34 104.01 110.22 Table 1: Values of critical load (𝑁𝑥 )𝑐𝑟 in N/mm. 0.9 4.04 80.34 1.9 5.88 116.94 1 4 79.45 2 6.25 124.15 6 Figure 2: Evolution of the critical load as a function of 𝑎/𝑏 for 𝑚 = 1. This analysis shows that the transition between buckling modes is strongly dependent on the 𝑎/𝑏 ratio, and that the critical load can be accurately determined from the curves or from the equation (17). Very long plates tend to split into several square half-waves during buckling, with an increasing critical load for high values of 𝑎/𝑏. 2.2 Buckling of a rectangular plate simply supported under compression in two perpendicular directions Consider a simply supported rectangular plate subjected to uniform compressive forces 𝑁𝑥 and 𝑁𝑦 applied in the longitudinal and transverse directions respectively, as shown in figure 3. Figure 3: Plate under compression in two perpendicular directions. 7 In this case, the critical buckling load is expressed as follows: 2 𝑚2 𝜋 2 𝑚2 𝜋 2 𝑚 2 𝜋 2 𝑛2 𝜋 2 𝑁𝑥 2 + 𝑁𝑦 2 = 𝐷 ( 2 + 2 ) 𝑎 𝑏 𝑎 𝑏 (21) where 𝑚 and 𝑛 represent the number of half-waves in the 𝑥 and 𝑦 directions respectively, and 𝐷 is the bending stiffness. The equation shows that the critical load depends not only on geometric (𝑎, 𝑏, ℎ) and mechanical (𝐸, 𝜈) parameters, but also on the coupling between the loads in the two directions (𝑁𝑥 , 𝑁𝑦 ). By introducing a relationship between 𝑁𝑥 and 𝑁𝑦 , such that 𝑁𝑥 = 𝛼𝑁𝑦 (with 𝛼 a nondimensional constant), we can reformulate the critical load in terms of a non-dimensional coefficient 𝐾𝑐𝑐 : 𝑁𝑥 = 𝐾𝑐𝑐 𝜋2𝐷 𝑏2 (38) where: 𝐾𝑐𝑐 = [(𝑚𝑏⁄𝑎)2 + 𝑛2 ]2 (𝑚𝑏⁄𝑎)2 + 𝑛2 (39) For a plate with a ratio 𝑎/𝑏 = 5 and typical mechanical properties (𝐸 = 220 GPa, 𝜈 = 0.3, ℎ/𝑏 = 0.01), calculations show that the optimal values of 𝑚, 𝑛 and 𝐾𝑐𝑐 depend on 𝛼, as shown in the table 2. When 𝐾𝑐𝑐 is minimal, the critical buckling load of the expression (23) can be used. 𝛼 𝑚 𝑛 𝐾𝑐𝑐 1 1 1 1.04 0.9 1 1 1.15 0 1 1 27.04 -1 1 1 -1.13 Table 2: 𝐾𝑐𝑐 as a function of 𝛼, 𝑚 and 𝑛. For 𝛼 = 1 (equal compression in both directions), the calculation gives 𝐾𝑐𝑐 = 1.04, and with 𝐷 = 1.84 × 104 N.mm, 𝑎 = 500 mm, 𝑏 = 100 mm, ℎ = 1 mm, the critical buckling load, (𝑁𝑥 )𝑐𝑟 , is 20. 66 N/mm, giving the smallest value of the critical buckling load, as shown in figure 4. 8 Figure 16: Critical buckling load, (𝑁𝑥 )𝑐𝑟 , as a function of parameters 𝛼 on the left and 𝐾𝑐𝑐 on the right. Negative values of 𝛼 (transverse tension) indicate a stabilizing effect, as confirmed by numerous experimental studies [8][9]. 2.3 Buckling of a uniformly compressed rectangular plate, simply supported along two opposite sides perpendicular to the direction of compression, with various boundary conditions along the other two sides The analysis of the buckling of a rectangular plate subjected to uniform compression along the 𝑥 axis, with different boundary conditions on opposite sides 𝑦 = 0 and 𝑦 = 𝑏, is based on well-established analytical formulations. Figure 5 represents this scenario. The analytical solutions allow us to calculate precisely the modal form of the deformations and the minimum critical value of 𝑁𝑥 . Figure 5: Plate under compression along 𝑥 with different boundary conditions at 𝑦 = 0, 𝑏. Previous studies showed that plates with asymmetric boundary conditions (e.g. one side free and one side simply supported) exhibit different buckling behavior [8] [10]. These studies 9 provide critical coefficients 𝐾 which allow the generalization of analytical results to different 𝑎/𝑏 ratios. In the case of uniform compression along the 𝑥 axis and with 𝑁𝑥 considered positive for compression, the critical buckling load is expressed as follows: 𝜕4𝑤 𝜕4𝑤 𝜕 4𝑤 𝑁𝑥 𝜕 2 𝑤 + 2 + = − 𝜕𝑥 4 𝜕𝑥 2 𝜕𝑦 2 𝜕𝑦 4 𝐷 𝑥2 (24) Assuming that the plate deforms in sinusoidal half-waves under the action of compressive forces, the solution to the equation (24) is as follows: 𝑤 = 𝑓(𝑦) sin 𝑚𝜋𝑥 𝑎 (25) where 𝑓(𝑦) is a function of 𝑦 only, which we will determine. These calculations show that the smallest value of 𝑁𝑥 is obtained by taking 𝑚 = 1 and assuming that the buckled plate has only a half-wave. Hence the critical load is expressed as follows: (𝑁𝑥 )𝑐𝑟 = 𝐾 𝜋2𝐷 𝑏2 (26) In this expression, 𝐾 is a numerical factor depending on the magnitude of the ratio 𝑎/𝑏. Its expression is: 𝐾 = (0.456 + 𝑏2 ) 𝑎2 (27) The values of the critical load are given in the table 3 with 𝐸 = 206.7 GPa 𝑎𝑛𝑑 𝜈 = 0.25 and ℎ/𝑏 = 0.01. 𝑎/𝑏 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 𝐾 4.456 1.456 0.900 0.706 0.616 0.567 0.537 0.518 0.505 0.496 80.722 26.376 16.312 12.789 11.159 10.273 9.739 9.393 9.155 8.985 (𝑁𝑥 )𝑐𝑟 Table 3: Analytical values of 𝐾 and (𝑁𝑥 )𝑐𝑟 when side y = 0 is in simple support and side 𝑦 = 𝑏 is free. A steel plate (𝐸 = 210 GPa, 𝜈 = 0.3, ℎ/𝑏 = 0.01) with dimensions a = 2b has been studied. Analytical solutions show that for /𝑏 = 2, 𝐾 = 0.706, and that the critical load Nx is about 12.8 N/mm. The results are consistent with the data in table 3. 2.4 Cylindrical column buckling Consider a column-beam of length 𝐿 simply supported at its ends, as shown in Figure 6. 10 Figure 6: Straight column under axial compression. The well-known equation governing column equilibrium in a slightly deformed form is: 𝐸𝐼𝑤 (𝑖𝑣) + 𝑃𝑤 ′′ = 0 (28) Although this equation takes into account the influence of geometric nonlinearity (in the presence of the term 𝑃𝑤 ′′ ), it is a linear differential equation (for fixed values of the parameter 𝑃). In this respect, it differs from the expressions corresponding to plates, cylindrical shells and general-form shells, which are nonlinear. The equation (28) has a trivial solution 𝑤 = 0, which represents the primary equilibrium path. Non-zero solutions are found only for discrete values of the applied load 𝑃. For such values, called eigenvalues, the equation has several solutions corresponding to the two straight and curved configurations of the beam-column. The solutions indicate the existence of bifurcation points on the primary equilibrium path. The smallest eigenvalue is called the critical load 𝑃𝑐𝑟 . The general solution of the equation with constant coefficients is of the form: 𝑤 = 𝐶1 sin 𝑘𝑥 + 𝐶2 cos 𝑘𝑥 + 𝐶3 𝑥 + 𝐶4 où 𝐶1 , 𝐶2 , 𝐶3 et 𝐶4 are constants (29) where 𝑘2 = 𝑃 𝐸𝐼 (30) The eigenvalues are determined by substituting the equation (29) into the appropriate boundary condition equations. For simple end supports, the boundary condition equations are: 𝑤 = 𝑤 ′′ = 0 à 𝑥 = 0, 𝐿 (31) Introducing the equation (29) into the equation (31) gives: 𝐶2 = 𝐶3 = 𝐶4 = 𝐶1 sin 𝑘𝐿 = 0 (32) For the column in deformed form, 𝐶1 must be non-zero. 11 For the non-zero value of 𝐶1 , the equations (32) are satisfied if and only if sin 𝑘𝐿 = 0 and 𝑘 = 𝑛𝜋⁄𝐿, where 𝑛 is a positive integer. The equations (29) and (32) give, for the shape of the buckled column, the solution: 𝑤 = 𝐶1 sin 𝑛𝜋𝑥 où 𝑛 = 1, 2, 3,… 𝐿 (33) and the relation 𝑘 = 𝑛𝜋⁄𝐿 with the definition of 𝑘 2 = 𝑃⁄𝐸𝐼 gives, for the eigenvalues, the expression: 𝜋 2 𝐸𝐼 𝑃=𝑛 𝐿2 2 (34) The smallest eigenvalue in this case corresponds to 𝑛 = 1. Thus, 𝜋 2 𝐸𝐼 𝑃𝑐𝑟 = 2 𝐿 (35) 2.5 Buckling of cylindrical shells under uniform axial compression Consider a cylindrical shell of thickness ℎ, radius 𝑅 and subjected to a uniform axial compressive force 𝑁 (positive for compression). If the cylindrical shell is uniformly compressed in one axial direction, buckling may occur at a certain value of the critical load. The critical value of the compressive force 𝑁𝑐𝑟 per unit length of the shell edge can be obtained using the energy method. As long as the shell remains cylindrical, the total deformation energy is equal to the total compression energy. However, when the buckling starts, the axial compression, the deformation of the mean surface in the circumferential direction and the bending of the shell must be added. Thus, the energy of shell deformation is increased; at the critical load value this increase in energy must be equal to the work done by the critical load when the cylinder shortens due to buckling. The differential equation for the buckling of a cylindrical shell is thus: 𝐷 𝑑4 𝑤 𝑑2 𝑤 𝐸ℎ + 𝑁 + =0 𝑑𝑥 4 𝑑𝑥 2 𝑅 2 (36) where 𝑥 is the axial coordinate, 𝑤 is the radial deflection and 𝐷 is the flexural rigidity modulus. For a simply supported cylindrical shell of length 𝐿, which is a multiple of the sinusoidal halfwaves 𝑚 in the compression direction, it is assumed that the radial displacements during buckling (the exact solution of the differential equation (36)) are of the form: 𝑤 = 𝐶 sin 𝑚𝜋𝑥 𝐿 (37) where 𝐶 is a constant. 12 Thus, the critical buckling load is expressed as follows: 𝐸ℎ2 𝑁𝑐𝑟 = ( ) √3(1 − 𝜈 2 ) 𝑅 1 (38) The critical buckling load is proportional to 𝐸ℎ2 ⁄𝑅 . Note that the critical buckling load depends on the mechanical properties of the material, thickness and radius, and is independent of the length of the cylindrical shell. 2.6 Multi-layer Shells The buckling behavior of multi-layer shells has been widely studied for improving structural strength while maintaining lightweight characteristics, though this increases sensitivity to imperfections [11] [12]. Strategies like stiffeners, honeycomb structures, and multilayer composites have been explored [13] [14] [15]. Obrecht’s numerical studies show that lightweight coatings enhance buckling resistance without adding much weight [16]. The anisotropic nature of laminates and their layup and stacking sequence critically affect mechanical properties and buckling performance [17]. On a macroscopic scale, unidirectional composites seem homogeneous and anisotropic, while on a microscopic level, they are heterogeneous with locally isotropic regions. Composite laminates, composed of plies stacked at various orientations, are examined in a shared coordinate system, where ply angles significantly affect overall behavior. 2.7 Influence of geometric defects Ideal theoretical models assume perfect shells, but real structures inevitably contain geometric and material imperfections. These imperfections significantly reduce the critical load and modify post-buckling behavior, as quantified analytically and confirmed numerically [13] [18] [19]. The sensitivity law expresses the critical load 𝜆∗ as a function of the amplitude of the initial imperfection 𝑎, the thickness of the structure ℎ, and other parameters. In particular, the most penalizing imperfections are those collinear with the bifurcation mode, giving a sensitivity law expressed as follows [20]: 𝜆∗ 𝑚 3√3(1 − 𝜈 2 ) 𝑎 𝜆∗ (1 − ) = | | 𝜆𝑐 2 ℎ 𝜆𝑐 (39) where 𝜆∗ is the effective critical load of the imperfect structure, 𝜆𝑐 is the critical load for a perfect structure, 𝜈 is the Poisson's ratio, and 𝑚 is a characteristic exponent depending on the case under consideration, worth 2 for case I and 3/2 for case II. Figure 7 shows how small 𝑎/ℎ ratios greatly reduce 𝜆∗ , especially for case I structures. Defects are either localized. Manufacturing variability influences imperfection types, which must be 13 integrated into stability models. A standard cylindrical shell under axial load is used to demonstrate the impact of imperfections, defined with displacements and geometric parameters. Figure 7: Influence of geometric imperfections on critical buckling load: comparison of case I and case II. 3 Numerical Modeling Abaqus software was used to model thin structures and to simulate the buckling phenomenon. Buckling of simply supported square and rectangular plates with aspect ratios a/b = 1 and 2, following a six-step process including geometry creation, material definition, load application, and mesh generation, was simulated. For a square plate with a = 100 mm and k = 4, the theoretical critical load (𝑁𝑥 )𝑐𝑟 is 79.45 N/mm, while the numerical result showed a 1.28% deviation, confirming the validity of the analytical model (Table 4). The first buckling mode shape from the simulation is illustrated in figure 8, highlighting strong agreement between theoretical and numerical outcomes. 14 Figure 8: Buckling profile of a square plate with 𝑎/𝑏 = 1 for 𝑚 = 1: the critical buckling load is 78.4 MPa. (𝑁𝑥 )𝑐𝑟 Analytical (N/mm) (𝑁𝑥 )𝑐𝑟 Numerical (N/mm) Difference (%) 79.45 78.431 1.28 Table 2. Analytical vs. numerical results for a buckled square plate. A rectangular plate with 𝑎/𝑏 = 2 was simulated using the same material and boundary conditions, with the configuration shown in Figure 9. The critical buckling load appears for mode 𝑚 = 2 and is 78.747 N/mm, compared to the analytical value of 79.45 MPa, giving a difference of 1.23%. The deformation confirms that the plate buckles into two square segments, validating the analytical model. The critical buckling load (𝑁𝑥 )𝑐𝑟 depends on plate geometry, number of half-waves, and mesh quality in numerical simulations. For moderate 𝑎/𝑏 ratios, short-plate assumptions apply, and (𝑁𝑥 )𝑐𝑟 is computed using equation (19); as 𝑎/𝑏 increases, the number of half-waves (𝑚 = 1, 2, 3, etc.) influences the buckling shape. Figure 10 shows the profile of the rectangular plate deformed in its central part and associated with the first buckling mode. In this case, we can see that, for 𝑚 = 𝑛 = 1, the critical buckling load, (𝑁𝑥 )𝑐𝑟 , is 25.32 N/mm. This shows that the difference between the analytical and numerical results is 22.56%. By approximating 𝛼 = 1 to 𝛼 = 0.8, the transverse load becomes 𝑁𝑦 = 𝑁𝑥 ⁄𝛼 = 1.25, yielding a reduced critical buckling load of 21.011 N/mm, with only a 1.7% difference from the analytical result, as shown in Figure 11. The critical load varies with 𝛼, and improved mesh refinement is needed to reduce discrepancies. This highlights the essential role of mesh quality in aligning numerical and analytical results. 15 Figure 9: Buckling profile of a rectangular plate with 𝑎/𝑏 = 1 for 𝑚 = 2: the critical buckling load is 78.747 N/mm. Figure 10: Buckled shape of a plate simply supported under biaxial compression. 16 Figure 11: Buckled shape of a plate simply supported under compression in two perpendicular directions with 𝑁𝑦 = 𝑁𝑥 ⁄𝛼 = 1.25. Figure 12 shows a rectangular plate with a/b = 2, steel properties (E = 210 GPa, ν = 0.3, h = 1 mm), where analytically (𝑁𝑥 )𝑐𝑟 = 14.02 N/mm and numerically 13.192 N/mm, yielding a 5.91% difference. The analytical model shows decreasing (𝑁𝑥 )𝑐𝑟 with increasing aspect ratio, while numerically, finer meshes further reduce the critical load. Numerical simulations indicate that buckling is most pronounced at the free end, with minimal deformation near the simply supported edge. A cylindrical beam-column with length 𝐿 = 500 mm, radius 𝑟 = 5 mm, Young’s modulus 𝐸 = 220 GPa, and Poisson’s ratio 𝜈 = 0.3 was studied. The shear modulus 𝜇 = 84.62 GPa and moment of inertia I = 490.63 mm4 were used to compute the analytical critical load 𝑃𝑐𝑟 = 4256.88 N. This result was validated numerically using a beam-column model. Boundary conditions (simple supports) and an axial load were applied to replicate compression, as shown in Figure 13. The numerical eigenvalue matched the analytical 𝑃𝑐𝑟 , confirming the model’s accuracy. 17 Figure 12: Buckled shape of a plate simply supported under compression in the 𝑥⃗ direction, simply supported on 𝑦 = 0 and freely supported on 𝑦 = 𝑏. Figure 13: Buckled shape of a simply supported column under axial compression. For an initially straight column, the straight configuration remains an equilibrium shape for all load levels, and any nearby curved shape marks a bifurcation and defines the critical buckling 18 load. The critical load is the smallest value for which a slightly curved equilibrium is possible. Using the general buckling equation (28) for all boundary conditions, one obtains the solution in equation (33) that leads to Euler’s critical load (35). This formula assumes purely elastic behavior and applies specifically to a beam simply supported at both ends. Similar procedures yield 𝑃𝑐𝑟 expressions for other support configurations. For simply supported–simply supported boundary conditions, the critical buckling load is given by equation (35): 𝑃𝑐𝑟1 = 𝜋 2 𝐸𝐼 𝐿2 (40) Numerically, the deformed column shape (Figure 13) aligns with the analytical prediction, validating the theoretical model. This agreement depends on correctly identifying the effective buckling length 𝐿 based on boundary conditions. The coefficient 𝑘, varying with support type, directly affects the critical load value in Euler’s formula. For fixed-fixed boundary conditions, the analytical critical buckling load is given by: 𝜋 2 𝐸𝐼 𝑃𝑐𝑟2 = 4 2 ou 𝑃𝑐𝑟2 = 4𝑃𝑐𝑟1 𝐿 (41) derived by reducing the buckling length to 𝐿/2, yielding 𝑃𝑐𝑟2 = 17027.52 N. Numerically, the critical load obtained is 17005 N (Figure 14), with a relative difference of 0.13%. This confirms strong agreement between analytical predictions and numerical results for this boundary case. Figure 14: Column fixed at its ends under axial compression. For a column fixed at one end and simply supported at the other, the analytical critical buckling load is given by: 𝜋 2 𝐸𝐼 𝑃𝑐𝑟3 = 2.04 2 ou 𝑃𝑐𝑟3 = 2.04𝑃𝑐𝑟1 = 8684.04 N 𝐿 (42) 19 Figure 15: Column fixed at one end and simply supported at the other, under axial compression. For a column fixed at one end and free at the other, the analytical critical buckling load is given by: 1 𝜋 2 𝐸𝐼 1 𝑃𝑐𝑟4 = ou 𝑃 = 𝑃 = 1064.22 N 𝑐𝑟 3 4 𝐿2 4 𝑐𝑟1 (43) The effective buckling length is 2𝐿, and the numerical result (Figure 16) closely matches, with a difference of 0.13%. This confirms the validity of the analytical prediction for this boundary condition. Figure 16: Column fixed at one end and freely supported at the other end. 20 In the case of a cylindrical column, the analytical study shows that the effective length factor k varies with boundary conditions, affecting the effective buckling length and thus the critical load. Numerically, the smallest eigenvalue (critical load) is sensitive to mesh quality, boundary conditions, geometry, and material nonlinearities. A cylindrical shell under axial compression is considered with 𝑅 = 100 mm, ℎ = 0.247 mm, 𝐸 = 220 GPa, 𝜈 = 0.3, and Batdorf parameter 𝑍 = 1000, yielding 𝐿 = 160.9 mm. The analytical critical load parameter is given by: 𝑁𝑐𝑟 = 𝐸ℎ𝜆𝑐𝑟 = 𝐸ℎ2 ( ) √3(1 − 𝜈 2 ) 𝑅 1 (44) leading to 𝑁𝑐𝑟 = 81.23 N/mm. Equation 44 is identical to equation (38). Numerically, the smallest eigenvalue is 73.073 N, close to the analytical result, confirming the validity of the analytical solutions. The buckling deformation shown in Figure 17 highlights sensitivity to geometric imperfections, with irregular sinusoidal half-waves observed. Figure 17: Cylindrical shell in buckled shape with some geometric imperfections. The numerically studied cylindrical composite shells, featuring CFRP (Carbon Fiber Reinforced Polymer) laminates with a total length of 700 mm, an effective length 520 mm, and a nominal thickness of 1.32 mm [21]. Two laminate configurations were analyzed: model 1 21 [45°/ − 45°]s and model 2 [0°/45°/ − 45°/0°], whose mechanical properties and solution types are detailed in Tables 5 and 6. The numerical simulations used S4R shell elements with fixed base boundary conditions and axial compression applied at the top. Properties Values 52000 Young’s Modulus 𝐸11 (MPa) Young’s Modulus 𝐸22 (MPa) 52000 2350 Shear Modulus 𝐺12 (MPa) 0.302 Poisson’s ratio 𝜈12 Table 5: Mechanical properties of CFRP plies [22]. Type solution Model 1 Model 2 Analytical solution 118.58 240.00 Experimental 112.94 161.22 Table 6: Comparison of buckling load (kN) [22]. Figures 18 and 19 illustrate the deformation of two CFRP cylindrical shells with different fiber orientations: Model 1 [45◦/ − 45◦] shows uniform isostress fields, while model 2 [0°/45°/ − 45°/0°] displays a more complex stress distribution. Model 1 exhibits a lower critical buckling load (120.551 kN) than model 2 (248.417 kN), highlighting the strong influence of fiber orientation on stiffness and stability. Figure 18: Critical buckling load for cylindrical shells made of CFRP material for the two models with different angles of orientation. 22 Figure 19: Different thickness configurations for each cylindrical shell made of CFRP material for both models. 4 Conclusion A buckling study was performed on various thin structures, such as cylindrical columns, rectangular plates, and cylindrical shells. Analytical solutions have been validated by numerical results obtained using the finite element method. Several cases have been studied in this paper, leading to the conclusion that the critical buckling load varies considerably as a function of geometry, mechanical properties, boundary conditions, and in particular imperfections in the case of cylindrical shells. Furthermore, the critical load corresponds to the smallest eigenvalue associated with the first buckling mode, which is the most sensitive to defects and variations in system parameters. During numerical analysis, it is imperative to refine the mesh until the solution converges, i.e. the material response no longer varies significantly with increasing mesh density. In addition, the appropriate choice of element types (e.g. shell elements for cylindrical shells, plate elements for plates, etc.) is crucial to obtain reliable and relevant results. These considerations ensure accurate modeling of the buckling phenomenon and contribute to the safety and optimization of structural designs. 23 5 References [1] Futura Sciences. Définition — flambage, sciences.com/sciences/definitions/physique-flambage-10695/. 2024. https://www.futura- [2] Springhetti Roberta, Rossetto Gabriel, and Bigoni Davide. Buckling of thin-walled cylinders from three-dimensional nonlinear elasticity. Journal of Elasticity, 154(1):297–323, 2023. [3] Bin Kamarudin Mohamad Norfaieqwan, Mohamed Ali Jaffar Syed, Aabid Abdul, and Ibrahim Yasser E. Buckling analysis of a thin-walled structure using finite element method and design of experiments. Aerospace, 9(10):541, 2022. [4] Brush Don O., Almroth Bo O., and Hutchinson J.W. Buckling of bars, plates, and shells. Engineering, Materials Science, 1975. [5] Leissa Arthur W. A review of laminated composite plate buckling. Applied Mechanics Reviews, 1987. [6] Kumar Shashi, Kant Lakshmi, Poddar Manoj Kumar, Yadav Chandra Bhushan Kumar, and Kumar Sumit. A review on buckling of the laminated composite panel under in-plane load. Engineering Research Express, 2024. [7] Cook Robert D. et al. Concepts and applications of finite element analysis. John Wiley and sons, 2007. [8] Timoshenko Stephen P. and Gere James M. Theory of elastic stability. Second Edition, McGraw- Hill Book Co. Inc., New York, 1961. [9] Jones Robert Millard. Buckling of bars, plates, and shells. Bull Ridge Corporation, 2006. [10] Bulson Philip Stanley. The stability of flat plates. (No Title), 1970. [11] Bushnell David. Computerized analysis of shells-governing equations. Computers & structures, 18(3):471–536, 1984. [12] Arbocz Jand Hol JMAM and de Vries J. The effect of initial imperfections on shell stability. Springer, 2002. [13] Koiter Warner Tjardus. On the stability of elastic equilibrium. National Aeronautics and Space Administration, 1967. [14] Carrera Erasmo. Evaluation of layerwise mixed theories for laminated plates analysis. AIAA journal, 36(5):830–839, 1998. [15] Carrera Erasmo. Theories and finite elements for multilayered plates and shells: a unified compact formulation with numerical assessment and benchmarking. Archives of Computational Methods in Engineering, 10:215–296, 2003. 24 [16] Obrecht H., Fuchs P., Reinicke U., Rosenthal B., and Walkowiak M. Influence of wall constructions on the load-carrying capability of light-weight structures. International Journal of Solids and Structures, 45(6):1513–1535, 2008. [17] Daniel Isaac M. and Ishai Ori. Engineering mechanics of composite materials, volume 3. Oxford University Press New York, 1994. [18] Koiter Warner Tjardus. Buckling and post-buckling behaviour of a cylindrical panel under axial compression. NLL-TR S. 476, 1956. [19] Ventsel Eduard, Krauthammer Theodor, and Carrera EJAMR. Thin plates and shells: theory, analysis, and applications. Appl. Mech. Rev., 55(4): B72–B73, 2002. [20] Hutchinson J.W., Koiter W.T., et al. Postbuckling theory. Appl. Mech. Rev, 23(12):1353– 1366, 1970. 24 [21] Bisagni Chiara. Experimental buckling of thin composite cylinders in compression. AIAA journal, 37(2):276–278, 1999. [22] Rehman Tahir Zia ul and Mandal P. Effect of asymmetric meshing on the buckling behavior of composite shells under axial compression. International Journal for Computational Methods in Engineering Science and Mechanics, 18(1):47–63, 2017. 25