Uploaded by

common.user2590

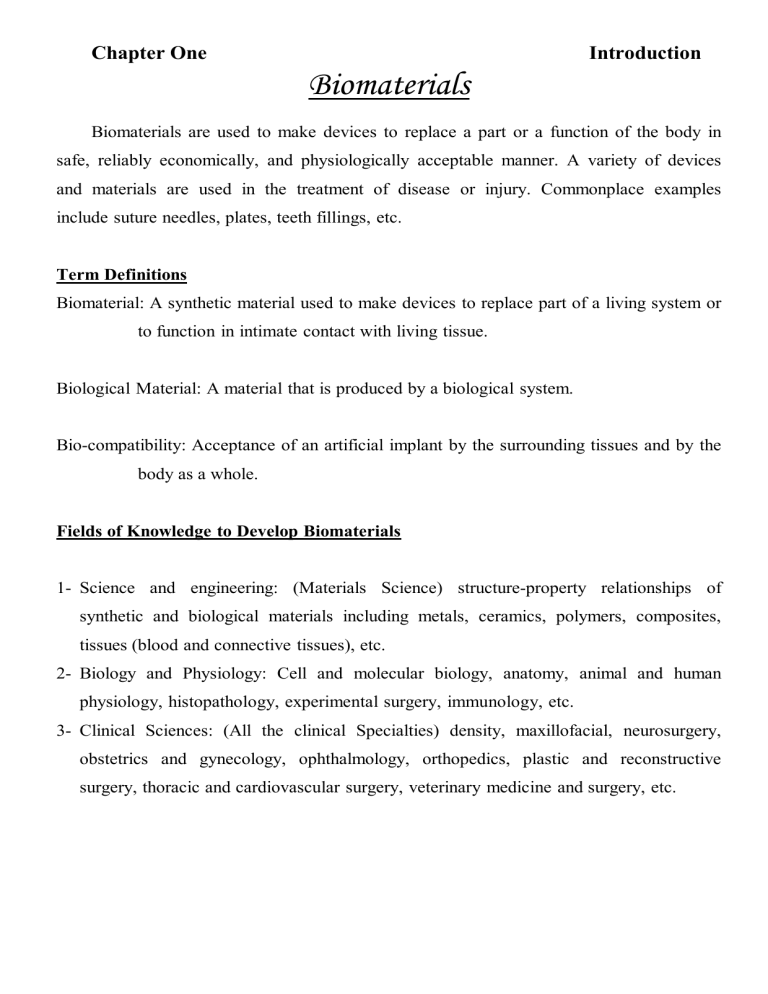

Biyomaterials