SENMAR

MODIFIED POLYETHYLENE COMPOUND

FOR AGRICULTURAL FILM APPLICATIONS

SENMAR , nano material, is an additive provides major benefits in the agricultural film applications.

Usage Areas:

• Greenhouse Film

• Mulch Film

• Solarization Film

Usage Rates

Greenhouse Film : %3 - %5

Mulch Film&solarization Film: %5 - %15

It is mixed into LDPE.

Physical Properties:

Features

Value

Melt index

Density

U.M.

Test Method

4-5

g/10min(190°C 5kg)

ASTM D 1238

2,0-2,50

g/cm³

ASTM D 792

Advantages

•

Increase the temperature inside the greenhouse and retains

moisture

•

Gives you the opportunity to harvest 5-10 days earlier.

•

Senmar absorbs infrared (IR) rays, also with its barrier

properties it provides 3-5°C increase in temprature by

maintaining the temperature and humidity inside the cover,

with high temprature and moisture product maturation is

achived 5-10 days earlier.

•

Reduces water drops formation on film surface.

•

By enhances acid, alkali and UV resistance of the film it

increases the film’s life.

•

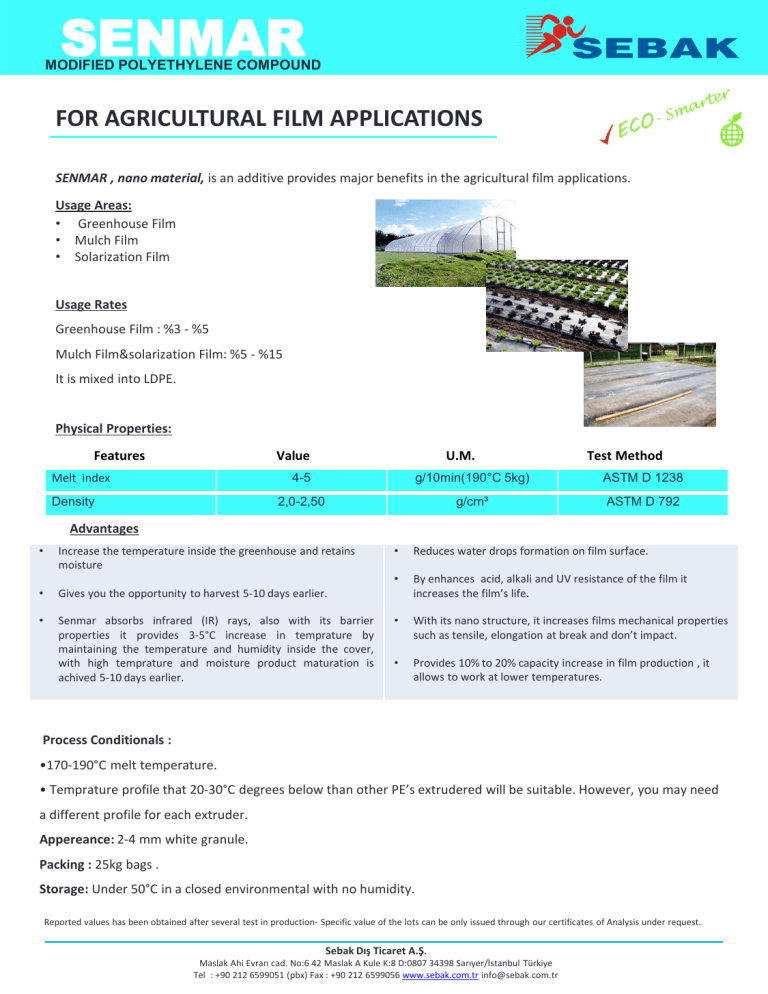

With its nano structure, it increases films mechanical properties

such as tensile, elongation at break and don’t impact.

•

Provides 10% to 20% capacity increase in film production , it

allows to work at lower temperatures.

Process Conditionals :

•170-190°C melt temperature.

• Temprature profile that 20-30°C degrees below than other PE’s extrudered will be suitable. However, you may need

a different profile for each extruder.

Appereance: 2-4 mm white granule.

Packing : 25kg bags .

Storage: Under 50°C in a closed environmental with no humidity.

Reported values has been obtained after several test in production- Specific value of the lots can be only issued through our certificates of Analysis under request.

Sebak Dış Ticaret A.Ş.

Maslak Ahi Evran cad. No:6 42 Maslak A Kule K:8 D:0807 34398 Sarıyer/İstanbul Türkiye

Tel : +90 212 6599051 (pbx) Fax : +90 212 6599056 www.sebak.com.tr [email protected]

SENMAR

MODIFIED POLYETHYLENE COMPOUND

FOR AGRICULTURAL FILM APPLICATIONS

Increase in Capacity

N/mm²

kg

Elongation at Break (10 micron film)

N/mm²

SENMAR AMOUNT %

SENMAR AMOUNT %

Dart Drop

N/mm²

gr

Tensile Strength at break

(10 micron film)

Tear Strength

Machine direction

SENMAR AMOUNT %

SENMAR AMOUNT %

SENMAR AMOUNT %

N/mm²

Tear Strength

Transverse

SENMAR AMOUNT %

gr(m²,gün)

Water Vapor Permeability

(15 micron film)

SENMAR AMOUNT %

Reported values has been obtained after several test in production- Specific value of the lots can be only issued through our certificates of Analysis under request.

Sebak Dış Ticaret A.Ş.

Maslak Ahi Evran cad. No:6 42 Maslak A Kule K:8 D:0807 34398 Sarıyer/İstanbul Türkiye

Tel : +90 212 6599051 (pbx) Fax : +90 212 6599056 www.sebak.com.tr [email protected]