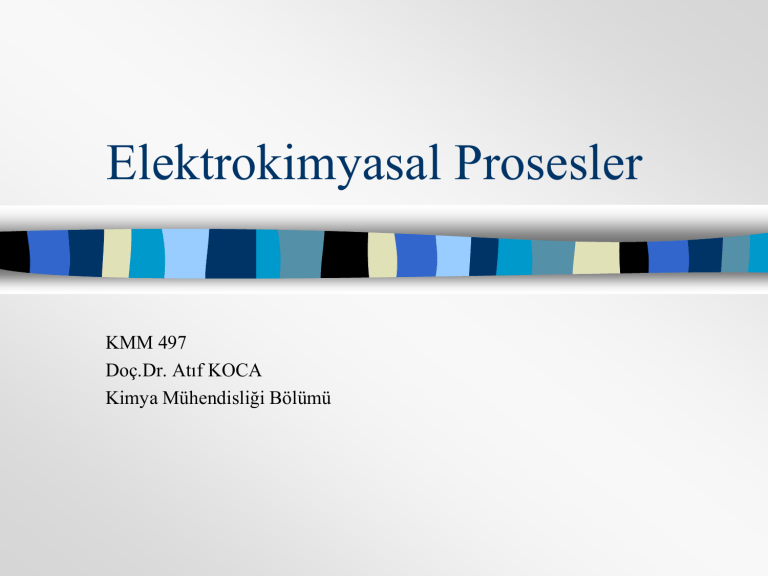

Elektrokimyasal Prosesler

advertisement

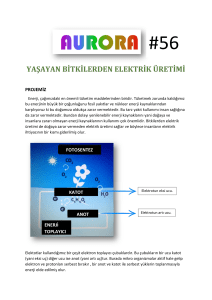

Elektrokimyasal Prosesler KMM 497 Doç.Dr. Atıf KOCA Kimya Mühendisliği Bölümü Elektrokimyasal Prosesler Sanayide; Kimyasal proseslerin Seçiciliğin artırılması Karışımların ayrıştırılması Atıklardaki kimyasalların geri kazanımı Toksik atıkların elimine edilmesi gibi proseslerin iyileştirilmesi için yeni teknolojilere ihtiyaç duyulmaktadır; Çözüm: Modern elektrokimyasal teknolojiler Elektrokimyasal Proseslerin Ticari Kullanımı + eElektroliz NaOH + H2 Cl2 OH- eCl- e- Na+ KATOT ANOT Katyon Değiştirici Membran 1/2 Cl2 (g) + e- H 2 O + e- 1/2 H2 (g) + OH- NaCl Klor-Alkali prosesi Elektrokimyasal Proseslerin Ticari Kullanımı Inorganik kimyasalların üretimi: Cl2/NaOH, KOH, ClO3-, ClO2-, BrO3-, H2, O2, F2, O3, gibi. Organik kimyasalların üretimi: Monomerler, fine chemicals, farmasötikler, zirai kimyasallar. Metal Ekstraksiyonu: Al, Na, K, Mg, Li, Cu, Zn, Ga. Atıkların geri kazanımı: Kimyasal saflaştırma ve ayırma: Su ve atık iyileştirme: Toksiklerin iyileştirilmesi: Toprak ıslahı: Atmosfer kontrolü: Elektrokimyasal Proseslerin Ticari Kullanımı Metal Ġşleme: elektrokaplama, elektroboyama, yüzey iyileştirmesi Elektronik Devrelerin Üretimi: Metal Üretimi : Korozyon Konyrolü: Pil, akü, batarya, yakıt pilleri: Sensörler: Elektrokimyasal Proseslerin Ticari Kullanımı Özellikle; atık dönüşümü ürün izolasyonu(ayırma) su ve atık iyileştirmesi proseslerinde; Atıklardan ağır geçiş metallerinin uzaklaştırılması:<< 1 ppm. ! Atıklardan organik maddelerin uzaklaştırılması:< 10 ppm. ! Sudan tuz uzaklaştırılması: < 200 ppm Seçici iyon uzaklaştırılması: NO3Kaplama atık sularından geçiş metallerinin eldesi Atık sulardan asit ve baz üretimi Deniz suyundan NaCl eldesi Kimyasal atıklardan organik asitlerin uzaklaştırılması Atık iyileştirmesi ile ClO-, H2O2, ve O3 üretimi Elektrokimyasal Proseslerin Sanayide Kullanımındaki Sorunlar Sanayide kullanılan kimyasal prosesler ile ilgili karşılaşılan uygun elektrokimyasal bir prosesle çözülebilecek problemlerin birçoğu; Ar&Ge (R&D) programlarının eksikliği Veya Elektrokimyasal teknolojiler hakkında yetersiz bilgi ve deneyim eksikliğinden kaynaklanmaktadır!!!!! Elektrokimya Elektrokimyasal Prosesler; – Enerji üretmek: Kendiliğinden gerçekleşen redoks reaksiyonlardan faydalanarak ( K > 1) VEYA – Kimyasal Üretmek: Enerji kullanarak kendiliğinden gerçekleşmeyen reaksiyonları gerçekleştirmek (K<1) Bütün elektrokimyasal prosesler yükseltgenme ve indirgenme reaksiyonlarının bir arada gerçekleştiği reaksiyonlardan oluşur Yükseltgenme – Indirgenme Reaksiyonları Yükseltgenme … – Elektron veren – Oksidasyon kademesinin artan – Oksijen eklenen – Hidrojen kaybeden 2 Mg + O2 2 MgO İndirgenme… – Elektron alan – Oksidasyon kademesinin azalan – Oksijen kaybeden eklenen – Hidrojen eklenen MgO + H2 Mg + H2O Redoks Reaksiyonların Belirlenmesi Bir elektrokimyasal reaksiyonda; yükseltgenme ve indirgenme reaksiyonları birlikte gerçekleşir. Bir kimyasal reaksiyonda türlerin oksidasyon kademesinde bir değişme varsa, bu reaksiyon bir redoks reaksiyondur: 2 Fe3+ + 2 I- 2 H2O 2 AgNO3 + Cu HCl + AgNO3 2 Fe2+ + I2 2 H2 + O2 2 Ag + Cu(NO3)2 AgCl + HNO3 Yükseltgen; – Diğer türleri yükseltgerken kendisi indirgenen tür. Ġndirgen; – Diğer türleri indirgerken kendisi yükseltgenen tür. 5 Fe2+ + MnO4- + 8 H+ H2 + CuO Zn + 2 HCl 5 Fe3+ + Mn2+ + 4 H2O Cu + H2O ZnCl2 + H2 Redoks Reaksiyonların Denkleştirilmesi; İndirgenme ve yükseltgenme yarı reaksiyonlarına ayırma Her Bir Yarı Reaksiyon için; H ve O hariç diğer elementlerin denkleştirilmesi “O’ denkleştirmek için, H2O (asidik) veya OH- (bazik) eklemek “H’ denkleştirmek için, H+ eklemek, Yük denkliği için, e- eklemek Her iki yarı reaksiyondaki e- sayısını eşitlemek Yarı reaksiyonları toplamak. Örnek Fe2+ + Cr2O72- Fe3+ + Cr3+ Fe2+ Fe3+ Cr2O72- Cr3+ Fe2+ Fe3+ + e- Cr2O72- 2 Cr3+ 6 Fe2+ Fe3+ + 6 e- Cr2O72- 2 Cr3+ + 7 H2O Cr2O72- + 14 H+ 2 Cr3+ + 7 H2O Cr2O72- + 14 H+ + 6 e- 2 Cr3+ + 7 H2O Cr2O72- + 6 Fe2+ + 14 H+ 2 Cr3+ + 6 Fe3+ + 7 H2O Asidik çözeltide denkleştirme; H2C2O4 + MnO4- Mn2+ + CO2 Bazik çözeltide denkleştirme; : CN- + MnO4- CNO- + MnO2 Mavi renkli CuSO4 çözeltisine metalik Zn eklendiğinde ne olur? Fiziksel Değişim; …… Zn (k) + CuSO4 (suda) ZnSO4 (suda) + Cu (k) Kimyasal Değişim; …… Enerji; …… Zn (s) + Cu2+ (aq) Zn2+ (aq) + Cu (s) Kimyasal Enerji – Elektrik enerjisi Zn Zn2+ + 2 eCu2+ + 2 e- Cu (yükseltgenme) (indirgenme) Zn ve Cu2+ bir araya geldiğinde, Zn den Cu2+ elektronlar kendiliğinden transfer olur; Fakat kendiliğinden olan bu reaksiyondan bir iş elde edilememiştir; Açığa çıkan kimyasal enerji ısı olarak çözeltiye verilir; Bu kimyasal enerjiden elektrik enerjisi nasıl elde edebiliriz????????????? Galvanik Piller Kendiliğinden gerşekleşen redoks reaksiyonlardan elektrik enerjisi elde etmek için dizayn edilen sistemler; Pil Potansiyeli & Elektromotor Kuvveti; Epil Yarı Epil pil potansiyellerinin farkı; =Ekind. – Eaind. Ekind. = katot yarı pil potansiyeli Eaind = anot yarı pil potansiyeli Yarı pil potansiyellerinin gerçek değerini ölçmek mümkün değildir.!!!!!!! Standart Hidrojen Elektrot (SHE) Tek bir elektrodun potansiyelini ölçmek mümkün değildir. Bir potansiyostat ile, İki elektrot arasındaki potansiyel farkını ölçmek mümkündür. Standart hidrojen elektrodun indirgenme potansiyeli KEYFĠ olarak bütün sıcaklıklarda 0 kabul edilmiştir. Herhangi bir elektrodun potansiyeli; SHE ile oluşturulan pil potansiyeli kullanılarak hesaplanır. 2 H+ + 2 e- H2 E° = 0 V E cell = + 0.76 V + = pil kurulduğu şekliyle kendiliğinden çalışabilmekte. Zn Zn2+ + 2 ereaksiyonu için yükseltgenme potansiyeli E°SHE= 0 V, olduğu için E cell = EZn = + 0.76 V . E oZn 2 / Zn 0.76 V Standart İndirgenme Potansiyelleri Standart Pil Potansiyelinin Hesaplanması 1. 2. 3. Anot ve katodun belirlenmesi Yarı reaksiyonların yazılması Standart pil potansiyelinin E°pil = E°indkatot - E°indanot denklemi kullanılarak hesaplanması E°(Cu2+/Cu)>E°(Zn2+/Zn) Cu katot ve Zn anot Katot reaksiyonu: Cu2+ + 2e- Cu E°(Cu2+/Cu) = +0.34 V Anot reaksiyonu: Zn Zn2+ + 2 eE°(Zn2+/Zn) = -0.76 V Pil reaksiyonu: Zn + Cu2+ Zn2+ + Cu E opil E oCu2 / Cu E oZn 2 / Zn 0,34 0,76 1,10 V Cu Zn Pil Şeması -Zn | Zn2+ (1.0 M) || Cu2+ (1.0 M) | Cu+ ANOT - ; KATOT + ANOT solda; KATOT sağda Konsantrasyonlar parantez içinde verilir | faz farkını ifade ederA vertical line represents a phase boundary || tuz köprüsü Pil Şeması; ÖRNEK Aşağıda şeması verilen pilin pil potansiyelini hesaplayınız: Mg | Mg2+ (1.0 M) || Ag+ (1.0 M) | Ag E oMg 2 / Mg 2,37 V E oAg / Ag 0,80 V Aşağıdaki reaksiyon kendiliğinden gerçekleşirmi ? (istemlimi?) [Fe2+] = 0.60 M ve [Cd2+] = 0.010 M ? Fe2+ (aq) + Cd (s) Fe (s) + Cd2+ (aq) E oFe2 / Fe 0.44 V E oCd2 / Cd 0.40 V 19.5 Redoks Reaksiyonların İstemliliği (Spontaneity) Go = - n F Eo Faraday n = transfer edilen elektron sayısı Michael (1791-1867) Faraday sabiti F = 96,500 C/mol e- 1F = 1 mol e-, 1 mol elektronun yükü 96,500 C/mol e Go = (mol e-)(C/mol e-)(V) = (mol e)(C/mol e-)(J/C) = J Pil Potansiyeline (Ecell) Konsantrasyonun Etkisi Nernst Denklemi: G = Go + RT ln Q ve (R = 8.314 J/(mol•K)) Go = - n F Eo - n F E = - n F Eº + RT ln Q RT EE ln Q nF 0 Walther Nernst (1864-1941) Dengede, G = 0 RT E ln K nF 0 0.0591 E log K n 0 Go = - n F Eo Go K Eocell Reaksiyon - >1 + istemli 0 1 0 denge + <1 - istemsiz Termodinamik Büyüklükler: Denge konsantrasyonları nın belirlenmesi pil pil pil Kalorimetre ve Entropi: S0 ve S0 Potansiyel Ölçümü: E0 ve E0cell Nernst Denklemi Aşağıdaki reaksiyonun pil potansiyelini (Epil ) hesaplayınız - Mg | Mg2+ (0.0050 M) || Ag+ (2.0 M) | Ag + E oMg 2 / Mg 2,37 V E oAg / Ag 0,80 V Nernst Denklemi Aşağıdaki reaksiyonun Denge sabitini hesaplayınız - Mg | Mg2+ (0.0050 M) || Ag+ (2.0 M) | Ag + E o 2 2,37 V E o 0,80 V Mg / Mg Ag / Ag Elektrot Türleri Metal-Metal iyonu Ag | Ag+ (M1) Ametal- Ametal iyonu Pt, H2 (p) | H+ (M1) Metal,-çözünmeyen tuzu Ag, AgCl(k) | KCl (M1) Amalgam Elektrot Ag (Hg) (M) | Ag+ (M1) Redox Elektrot Pt | Fe2+ (M1), Fe3+ (M1) Referans elektrot (SCE) Hg | Hg2Cl2, KCl(doy) (potansiyeli sabit) Aşağıda şeması verilen pilin pil potansiyelini hesaplayınız Pt|Cr2O72- (0,20 M), Cr3+ (0,10 M), H+ (0,001 M) ||KCl(doy) , Hg2Cl2 | Hg Aşağıda reaksiyonu verilen pillerin pil potansiyelini hesaplayınız Ag+ (0,1 M) + Cd (s) Ag (s) + Cd2+ (0,2 M) H2 (1,0 atm, g) + Ag+ (0,2 M) H2 (0,1 atm, g) + Cl2 (1,0 atm, g) H2 (0,1 atm, g) + AgCl (k) Ag (s) + H+ (0,1 M) HCl (0,1 M) Ag (s) + HCl (0,2 M) Konsantrasyon Pilleri Elektrolit Konsantrasyon Pilleri - Ag | Ag+ (M1) || Ag+ (M2) | Ag + Elektrolit Konsantrasyon Pilleri - Ag (Hg) (M1(Ag)) | Ag+ (M) | (M2(Ag)) Ag (Hg) + Problem: E oHg 2 / Hg 2 0,920 V 2 Olduğuna göre E oHg 2 / Hg ? ve E oHg 2 / Hg 0,789 V 2 Electrolitik Piller yükseltgenme H2O → O2(g) + 4 H+ + 2 e– E° = -1.23 V ve indirgenme 2 H+ + 2 e– → H2 (g) E° = 0.00 V Net reaksiyon 2 H2O + 4 e– → H2(g) + O2(g) E° = -1.23 V !!!!!!!! Elektroliz !!!!!! Sulu sodyum klorür çözeltisinin elektrolizi Olası katot reaksiyonları: 2 H2O + 2 e- H2 +2OHNa+ + e- Na Olası katot reaksiyonları : 2 Cl- Cl2 + 2 e2 H2O O2 + 4 H+ + 4 e- E° = -0.83 V E° = -2.71 V E° = -1.36 V E° = -1.23 V Net pil reaksiyon:………………………………….. Sodyum klorür eriyiğinin elektrolizi Anot: Catot: net: 2 Cl- () Cl2 (g) + 2 e2 Na+ () + 2 e- Na() 2 Cl- () 2 Na+ () Cl2 (g) + Na() Elektroliz Prosesleri Faraday Yasası • • • Metal kaplama Metal saflaştırma Metal üretimi Elektrokaplama Hücresi I V catot CuSO4 çözeltisi anot Pt elektrot: 2 H2O –> O2 + 4H+ + 4e- “yükseltgenme" “indirgenme" Cu2+ + 2e- –> Cu(0) Cu(0) –> Cu2+ + 2e- Quantitative Elektroliz 1 F = 96467 C A i.t m x n F 25x50x0 cm ebatlarındaki bir demir şerit bakır ile kaplanmak isteniyor. 0.15 i/dm2 akım yoğunluğunda 2 mikrometreCu kaplamak için ne kadar süreyle elektroliz yapılmalıdır (dCu=7.8 g/cm3.) 0.452 A alım geçirilerek 1.5 saat süreyle gercekleştirilen NaCl eriyiğinin elektrolizde anot ve katot ürünlerinin öiktarlarını hesaplayınız. Metal ayırma prosesleri Ag+, Cu2+, H+, ve Pb2+ iyonlarının 1 M lık çözeltisinin elektrolizinde anot ve katotta gerçekleşen olayları sıralayınız . Ag+ + e- Ag E oAg / Ag 0.80 V 2H+ + 2e- H2 E oH / H 0.00 V 2 Cu2+ + 2e- Cu E oCu2 / Cu 0.34 V Pb2+ + 2e- Pb E oPb2 / Pb 0.126 V Aşırı gerilim dikkate alınmaz ise Ag+, Cu2+, H+, ve Pb2+ sırayla 0.799 V; 0.337 V; 0.000 V; -0.126 V yarı pil potansiyellerinde katotta indigenirler !!!!!!!!!!!!!!!!!!! 0.799 E oAg / Ag Aşırı gerilim sırayı değiştirebilir; Cu (H) 0.60 V Pb (H) 1.56 V E d (anot ) E rev (anot ) 0.337 E oCu2 / Cu o 0.000 E H / H 2 -0.126 E oPb2 / Pb E d (katot ) E rev (katot ) E d (H)Cu E rev H Ag (H) E d (H)Cu 0 0.60 0.60 V E d (H)Pb E rev H Pb (H) E d (H)Pb 0 1.56 1.56 V Polarizasyon Elektrokimyasal bir pilden akım geçtiği zaman; pil potansiyeli anot ve katotun yarı pil potansiyellerinin farkına eşit değildir. ECell=Ecathode-Eanode-IR + IR düşüşü ve polarizasyondan dolayı; Elektrolitik hücreyi çalıştırmak için daha fazla potansiyel uygulamak gerekir. Ve Galvanik gücrede de daha az potansiyel elde edilir. Polarizasyonun sebepleri: Elektrot yüzeyinde gerçekleşen reaksiyonun sınırlanmasın dan kaynaklanmaktadır. Kütle transferi konsantrasyon Ara ürünler Adsorpsiyon, desorpsiyon ve kristalizasyon gibi Polarizasyon Konsantrasyon Polarizasyonu reaktiflerin elektrot yüzeyine yeterince hızlı taşınmaması veya ürünlerin yeterince hızlı uzaklaşmamasından dolayı elektron transfer hızını karşılayacak yeterli akım taşınamamaktadır. Difüzyon: Migrasyon: Konveksiyon: Kinetik Polarizasyon: Elektrokimyasal reaksiyonların Mekanizması elektrot Elektrot-çözelti arayüzeyi Oyüzey Bulk çözelti Kütle transferi O’yüzey Elektron transferi O’ ads. Kütle transferi Obulk Cu|Cu2+ (0,10 M) || Cd2+ (0,10 M) | Cd pilinin iç direnci 4,0 dur. a) 0,020 A akım geçmesi için uygulanması gereken pil potansiyelini bulunuz. (elektrolitik pil) b) 0,020 A akım geçmesi için uygulanması gereken pil potansiyelini bulunuz. (galvanik pil) Elektrolitik bir pilde bulunan iyonların konsantrasyonları: [Ag+]=0.1 M, [Pb2+]=0,02 M, [Cd2+]=0,01 M, [Zn2+]=0,05 M, ve pH =3 a) elektrotlarda ayçma sırasına göre sıralayınız. b) elektrolizin başlangıç potansiyelini bulunuz. (H): Ag = 0,2, Pb = 0,4, Cd = 0,22 ve Zn = 0.7 V (O) Pt= 0.66 V 0.1 M Cu2+ yi 0.1 M Zn2+ iyonundan ayırmak mümkünmüdür? Eo Cu2+/Cu = 0.337 V; Eo Zn2+/Zn = -0.763 V; 0.1 M Cu2+ yi 0.1 M Zn2+ iyonundan ayırmak mümkünmüdür? Eo Cu2+/Cu = 0.337 V; Eo Zn2+/Zn = -0.763 V; RT E Cu2 Cu E Cu2 Cu ln M Cu2 nF -0.763 = 0.337 + 0.05916lg MCu2+ CCu2+ aCu2+ = 2.5410-19 mol dm-3 0,001 M Cu2+ iyonunu 0,001 M Pb2+ iyonundan elektroliz ile ayırmak mümkümmüdür. 0,5 N CdCl2 çözeltisi Pt anot ve Cd katot ile elektroliz ediliyor. a) Elektrolizin başlaması için gerekli minimum potansiyeli bulunuz. b) Cd ile birlikte hidrojende çıkması için gerekli PH yi bulunuz. Elektrokaplama Anot: Ag – e- Ag+ Katot: Ag+ + e- Ag Alaşım eldesi: Zn-Fe, Cu-Zn Kaşımların elektrokaplaması: Ni-PTFE, Ni-Diamond Gümüş kaplı çaydanlık Pirinç Kaplama Eo Cu2+/Cu = 0.337 V; Eo Zn2+/Zn = -0.763 V; CCu2+ aCu2+ = 2.5410-19 mol dm-3 Pirinç kaplamasının Cu2+ ve Zn2+ çözeltisinden eldesi mümkün değildir. ???????????????????? Pirinç Kaplama Eo Cu2+/Cu = 0.337 V; Eo Zn2+/Zn = -0.763 V; CCu2+ aCu2+ = 2.5410-19 mol dm-3 Pirinç kaplamasının Cu2+ ve Zn2+ çözeltisinden eldesi mümkün değildir. ???????????????????? Eo Cu(CN)3-/Cu = -1.03 V; E0 Zn(CN)42-/Zn = -1.12 V; E < 0.2 V Zn ve Cu pirinç olarak kaplanır. Sn eklenirse ne olur Metal saflaştırma (electrorefining) Korozyon Korozyon maddelerin çevreyle etkileşimleri sonucu bozunması olayı Korozyon Metallerin yükseltgenerek aşınması olayı Yükseltgenme: Fe(k) İndirgenme: Fe2+(suda) + 2 e– O2(g) + 4 H+(suda) + 4 e– Net reaksiyon: 2 Fe(k) + O2(g) + 4 H+(suda) 2 H2O(s) 2 Fe2+(suda) + 2 H2O(s) 4 Fe + 3O2 + 2 H2O → 4 FeOOH 2Fe OOH → Fe2O3 + H2O Yüksek sıcaklıkta; 3 Fe + 4 H2O → Fe3O4 (manyetit) + 4 H2 Metal Korozyonu M → Mz+ + z ez e- + Z/4 O2 → Z/2 O2M + Z/4 O2 → MOZ/2 (yükseltgenme) (indirgenme) (toplam) Örnek: Zn → Zn2+ + 2 e2 HCl + 2e- → H2 + 2 Cl- (2 H+ + 2 e- → H2) Zn + HCl → H2 + ZnCl (Zn+ + Cl-) Korozyon metal çözünmesi; ANODİK: M Mn+ + n e(örn. Fe Fe 2+ + 2 e-) olası KATOT reaksiyonları: – – – – – Hidrojen indirgenmesi (asidic) 2 H+ + 2 e- H2 Oksijen indirgenmesi (asidic) O2 + 4H+ + 4 e- 2 H2O Oksijen indirgenmesi (nötr veya bazik) O2 + 2 H2O + 4 e- 4 OHMetal indirgenmesi M3+ + e- M2+ Metal birikimi M+ + e- M Çoklu katodik reaksiyonlar metal korozyonunu kolaylaştırırhızlandırır. Metaller havalandırılmış (aerated) asidik çözeltilerde daha kolay ve hızlı oksitlenirler. – havalandırılmış (aerated) asidik çözeltilerde: 2 H+ + 2 e- H2 O2 + 4H+ + 4 e- 2 H2O – Fe3+ safsızlığı (asitlerde sıkça bulunur): Fe3+ + e- Fe2+ ÖRNEĞĠN: Nötr veya alkali ortamda; + 2 Fe 2 Fe2+ + 4 eO2 + 2 H2O + 4 e- 4 OH- 2 Fe + O2 + 2 H2O 2 Fe2+ + 4 OHFe2+ çökeleği tekrar yükseltgenerek pasa dönüşür: 2 Fe(OH)2 ↓ + 1/2 O2 + H2O → 2 Fe(OH)3 MAGNETİT in ÇÖZÜNMESİ Fe3O4 + 8H+ +2e- 3Fe2+ + 4H2O 0.0591 [ Fe3O4 ][ H ]8 E 0.981 log n [ Fe 2 ]3[ H 2O]4 or 0.0591 [ H ]8 E 0.981 log 2 [ Fe 2 ]3 0.0591* 8 0.0591* 3 0.981 log[ H ] log[ Fe 2 ] 2 2 0.981 0.236 pH 0.0885 log[ Fe 2 ]volt Pourbaix diagram, olası tüm reaksiyonları vermektedir. Pourbaix Diagrams Pourbaix or E-pH diagrams depict the thermodynamically form of an element as a function of potential and pH. The Pourbaix diagram is a type of predominance diagram -- it shows the predominate form in an element will exist under a given set of environmental conditions. These diagrams give a visual representation of the oxidizing and reducing abilities of the major stable compounds of an element and are used frequently in geochemical, environmental and corrosion applications. Pourbaix diagrams display thermodynamically preferred species. Kinetics is not incorporated. How to Read a Pourbaix Diagrams Vertical lines separate species that are in acid-base equilibrium. Non vertical lines separate species related by redox equilibria. Horizontal lines separate species in redox equilibria not involving hydrogen or hydroxide ions. Diagonal boundaries separate species in redox equilibria in which hydroxide or hydrogen ions are involved. Dashed lines enclose the practical region of stability of the water solvent to oxidation or reduction. Pourbaix diagram ________ asit-baz dengesine göre türleri ayırır (a çizgisi) o a) Fe3+ Fe(OH)3 ile dengede olduğu pH (0.5 M-0.5 M) konsantrasyon değişirse pH da değişir. o Toplam demir konsantrasyonu = 1M için pH =1,7; o Toplam demir konsantrasyonu = 1 10-6 M olursa pH =4,2; Pourbaix diagram redoks dengesine göre türleri ayırır (c) türlerin redoks dengesi hydrogen veya hidroksil iyonları içermez (yatay çift çizgi; b) türlerin redoks dengesi hydrogen veya hidroksil iyonları içerir. Diagonal çift çizgi (c) diagonal sınırlar negatif eğimli; çünkü bazik ortamda oksitlenmiş türler kararlıdır. Pourbaix diagram --------- suyun teorik olarak kararlı olduğu bölgeleri ( d & f) ……… pratik olarak karalı oldukları bölgeri(e & g) gösterir. d) oksijenle doymuş suyun oksitlenme sınırı; bu potansiyelin üzerinde su oksitlenir. 2 H2O + 4 H+ (aq) O2 + 4 e- Eo = +1.229 V e ) pratikte, yaklaşık 0.5 V aşırı gerilimden dolayı yaklaşık 1.80 V üzerinde oksitlenir ( e) Pourbaix diagram f) hidrojen ile doyurulmuş suyun potansiyeli. Bu seviyenin altında su hidrojene indirgenir. (teorik) 2 H+ + 2 eH2 Eo = +1.229 V G) hidrojen ile doyurulmuş suyun potansiyeli. Bu seviyenin altında su hidrojene indirgenir. (pratikaşırıgerilim) Pourbaix diagram 1. the chemical form of iron that is the strongest oxidizing agent. the form of iron that is the strongest reducing agent the form of iron that would predominate in a neutral solution at a potential of 0.00V the standard reduction potential for the reduction of Fe2+ to Fe metal Potansiyel The Pourbaix (E-pH) Diagram 2.0 1.6 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -1.6 2H2O = O2 + 4H+ + 4eDenge potansiyeli pH ile azalır O2 kararlı 2H+ + 2e- = H2 denge potansiyeli pH ile H2O kararlı azalır H2 kararlıpH = - log [H+] 0 7 14 Pourbaix Diagram: Zn denge 2.0 Zn(OH)2 + 2OH- ZnO22- + 2H2O 1.6 denge Zn2+ + 2OH- Zn(OH)2 1.2 Potansiyel 0.8 Zn(OH)2 0.4 Kararlı 0.0 katı Zn2+ denge - Zn(OH) + 2eÇözeltide Zn + 2OH 2 denge kararlı Zn Zn2+ + 2e- -0.4 Denge -0.822- + 2H2O + 2eZn + 4OH- ZnO -1.2 ZnO22kararlı Zn metal kararlı -1.6 0 7 14 Pourbaix Diagram:Zn Korozyon kuvvetli oksidant gerektirir. 2.0 1.6 Potansiyel 0.8 Zn(OH)2 KOROZYON 0.4 KOROZYON PASİFLEŞME Korozyon O2 indirgenmesi ile gerçekleşir. 1.2 Kararlı Korozyon H2 çıkışı ile ZnO 2Korozyon olası,2fakat katı kozosyon katı gerçekleşir. Çözeltide ürünü ile engellenir. Zn2+ çözeltide 0.0 -0.4 kararlı kararlı -0.8 -1.2 KARARLI Zn karalı -1.6 0 Termodinamik olarak kozozyon mümkün değil 7 14 Pourbaix Diagram: Mn Pourbaix Diagrams Pourbaix or E-pH diagrams depict the thermodynamically form of an element as a function of potential and pH. The Pourbaix diagram is a type of predominance diagram -- it shows the predominate form in an element will exist under a given set of environmental conditions. These diagrams give a visual representation of the oxidizing and reducing abilities of the major stable compounds of an element and are used frequently in geochemical, environmental and corrosion applications. Pourbaix diagrams display thermodynamically preferred species. Kinetics is not incorporated. Korozyondan KORUNMA Metallerin Pasifleşmesi Boyama, kaplama Katodik koruma Galvanizleme Zn, Al veya Cr !!!!!!!!!!!!!!! Galvanize Demir Katodik KORUMA Katodik KORUMA Elektrik Akımı ile KORUMA Sanayi pillerinin Sınıflandırılması Yakıt Primer Sekonder piller yükseltgen Yakıt pilleri Piller ENERJİ ENERJİ ENERJİ ÜRÜN (H2O) Recharge ENERJİ Volta Pili (1800) Alessandro Volta 1745 - 1827 NaCl çözeltisi ile nemlendirilmiş kağıt Cu Zn Primer Piller Leclanché pili (1866) Modern Zn-Mn pili Georges Leclanché (1839-1882) Anot: Zn Zn2+ + 2e- Kapak Zn kap MnO2 pasta (KATOT) Karbon Çubuk ANOT NH4OH ELEKTROLİT Gaz boşluğu Katot: 2MnO2 + 2H2O +2e- 2MnOOH + 2OHZn kap elektrolit: Zn2+ 2NH4Cl +2OH- Zn(NH3)Cl2 + 2H2O MnO3)Cl 2MnO2 + Zn + 2NH4Cl 2MnOOH + Zn(NH 2 pasta 2 (KATOT) Karbon Çubuk (ANOT) Jel Elektrolit Primer Piller Zn-Mn Alkali pilleri MnO2 pasta (KATOT) Jel Elektrolit Gözenekli Zn (ANOT) Anot: Zn + 2OH- - 2e- Zn(OH)2 Katot: MnO2 + H2O +1e- MnOOH + OHaaaaaaaaa MnOOH + H2O +e- Mn(OH)2 + OH- Zn-Hava Pili Anot: Zn + 2OH- - 2e- Zn(OH)2 Katot: 1/2 O2 + H2O + 2e- Zn(OH)2 Sekonder (rechargeable) piller Kurşun-Asit akü Kurşun-Asit akü E=2.06 V Pb PbO2 Güvenlik vanası 36% H2SO4 Pb+(2H++SO42-)-2e- discharge charge PbSO4+ 2H+ PbSO4 PbO PbO2 2++Pb Pb++HH2SO 44 2SO PbO2+(2H++SO42-)+2H++2ePbSO4+H2O discharge charge PbO2 pasta - Pb-ızgara (KATOT) PbSO4 discharge charge 2PbSO 2PbSO4 4++2H 2H2O 2O Pb pasta Pb-ızgara (ANOT) Gözenekli ayıraç Sekonder (rechargeable) piller Lityum-iyon pili Katot: Discharge LiMeO2 - xe- CHARGE DISCHARGE Li1-xMeO2 + xLi+ Anot: C + xLi+ + xe- Charge CHARGE CLix DISCHARGE Anot(CLix) Katot (LiMexOy) Negatif kutup LiCoO2 –ticari pillerde kullanılır LiNiO2, LiMn2O4 -amaçlanmakta Ayıraç Aluminyum kap Pozitif kutup Sekonder (rechargeable) piller Nikel-Metal hidrür pilleri Katot: NiOOH + H2O - e- CHARGE DISCHARGE Ni(OH)2 + OH- Anot: Me-H + OH- + e- CHARGE DISCHARGE Me + H2O YAKIT PİLİ - Fuel Cells Anot: Catot: Pil reaks.: 2 H2 (g) + 4 OH- (suda) 2 H2O (s) + 4 eO2 (g) + 2 H2O (s) + 4 e- 4 OH- (suda) 2 H2 (g) + O2 (g) 2 H2O (s) YAKIT PİLLERİ Voltajın artırılması: Akımın artırılması: pillerin seri olarak bağlanması Pil yığını • sıcaklık artışı ANOT ELEKTROLİT KATOT KATOT ANOT ELEKTROLİT ANOT • elektrot-elektrolit ara yüzeyinin artırılması • katalizör kullanımı Katot katalizör Anot katalizör Bipolar elektrot H2 O2 ANOT ELEKTROLİT KATOT Yüzlercesinin yığını ELEKTROLİT ÜNİTESİ KATOT ELEKTROLİT ANOT KATOT ELEKTROLİT KATOT ANOT ANOT ELEKTROLİT ELEKTROLİT KATOT KATOTE Bipolar TABAKA Fosforik Asit Yakıt pili (PAFC) SiC gözenekli matrix içinde elektrolit O2 Pt-katalizörler (anot veya katot) Gaz (H2 veya O2) PACF parametreleri: Atmosferik basınçta Akım yoğunluğu - 200- 400 mA cm-2 Tek hücre potansiyeli - 600-800 mV sıcaklık - 220 oC H2 Yakıt pillerinde sıvı elektrolitlerin dezavantajları Düşük çalışma sıcaklığı ! (reaksiyon yavaş, katalizörler pahalı Üç fazlı sistemin oluşturulmasının zorluğu yakıt geçişi kolaylığı! H2 O2 Anot sıvı elektrolit Katot Proton Exchange Membrane Yakıt pili (PEMFC) H2O +Hava (O2) H2 Nafion® membran Akım kollektörü/gaz dağıtıcısı Katalizör destekli karbon tabaka H+ H2 geçişi H2 - Hava (O2) + YAKIT PİLİ - Fuel Cells POTANSİYOMETRİK TİTRASYON POTANSİYOMETRİK TİTRASYON Reaktif/ Titrant Büret motoru pH/mV kontrolü Büret Çalışma elektrodu Referans elektrot Analit Magnetik karıştırıcı Ekran POTANSİYOMETRİK TİTRASYON pH Elektrot: - Ag, AgCl(k) | HCl (1.0 M) |CM | || HCl (?? M) ||Referans elektrode + E pil E K E A 0 H RT RT in E pil E AgCl/ Ag ln Cl ln E SCE nF nF H out H RT in E pil E AgCl/ Ag ln E SCE nF H out 1 RT E E pil E * ln SCE nF H out E pil E pil E 0.059 logH E 0.059pH E * * out E SCE SCE POTANSİYOMETRİK TİTRASYON pH Elektrot: - Ag, AgCl(k) | HCl (1.0 M) |CM | || HCl (?? M) ||Referans elektrode + Junction Potansiyeli H in RT ln nF H out Problem; Epil = 0,517 V ise pH = ? POTANSİYOMETRİK TİTRASYON Çökelme titrasyonları: - Ag; AgCl (k) | Cl- (?? M) ||Referans elektrode + VAg = 0 ; AgCl(k) e Ag(k) Cl E oAgCl/ Ag 0.222 V VAg > 0 ; [Cl-] Eşdeğer noktada: [Cl-] = [Ag+] E pil E K E A RT E pil E SCE E 0AgCl/ Ag ln Cl nF 100,0 mL ??? M NaCl ün 0,100 M AgNO3 ile potansiyometrik titrasyonunda; 15,0 mL , AgNO3 eklendiğinde Epil +0.095 V ise; (a) [Cl–] (c) AgCl nin Kçç nedir?. POTANSİYOMETRİK TİTRASYON Çökelme titrasyonları: I- ve Cl- iyonları içeren bir çözeltinin Ag+ ile potansiyometrik titrasyonu; - Ag| Cl- (?? M) ; I- (?? M) ||Referans elektrode + AgCl(k) e Ag(k) Cl AgI(k) e Ag(k) I E oAgCl/ Ag 0.222 V E oAgI/ Ag 0.152 V E pil E K E A RT E pil E SCE E 0AgCl/ Ag ln Cl nF 100,0 mL 0.005 M NaCl ve0.005 M NaI karışımının 0,100 M AgNO3 ile potansiyometrik titrasyonunun E-V; E/ V- V ; E2/ V2 - V grafiklerini çiziniz Titration of 2.433mmol of chloride ion with 0.1000M silver nitrate. (a) Titration curve. (b) First-derivative curve. (c) Second-derivative curve. POTANSİYOMETRİK TİTRASYON Redoks titrasyonları: Fe2+ çözeltinin Ce4+ ile potansiyometrik titrasyonu; Fe+2 + Ce+4 <=> Ce+3 + Fe+3 - Pt | Fe2+ (?? M) ; Fe3+ (?? M) ||Referans elektrode + AgCl(k) e Ag(k) Cl AgI(k) e Ag(k) I E oAgCl/ Ag 0.222 V E oAgI/ Ag 0.152 V 50.00 mL 0.0500 M Fe+2 çözeltisinin 0.1000 M Ce+4 ile 1.0 M H2SO4ortamındaki potansiyometrik titrasyonunun E-V; E/ V- V ; E2/ V2 - V grafiklerini çiziniz Fe+2 + Ce+4 <=> Ce+3 + Fe+3 E = Eo - (0.0592/n) log([red]/[ox]) 0.00 mL Ce+4 eklendiğinde , başlangıç noktası; Ce+4 yok; [Fe+3] çok az ve bilinmiyor; E ? 15.00 mL Ce+4 eklendiğinde, VFeMFe > VCeMCe [Fe+3] VCe MCe (15.00 mL)(0.1000 M) = --------------- = ---------------------------VFe + VCe (50.00 + 15.00)mL [Fe+2] VFe MFe - VCe MCe = -----------------------VFe + VCe [Fe+2] (50.00 mL)(0.0500 M) - (15.00 mL)(0.1000 M) -2 = -------------------------------------------------------= 1.54 x 10 M = 2.308 x 10-2 M (50.00 + 15.00)mL E = Eo - (0.0592/n) log([red]/[ox])= E = Eo - (0.0592/n) log([red]/[ox]) E = Eo - (0.0592/n) log([red]/[ox]) E = 0.68 - (0.0592/n) log([1.54 x 10-2 ]/[2.308 x 10-2 M]) = 0.69 V 25.00 mL Ce+4 eklendiğinde, VFeMFe = VCeMCe Eşdeğer nokta; EA =EC EoCe = 1.44 V POTANSİYOMETRİK TİTRASYON POTANSİYOMETRİK TİTRASYON Electroanalytical methods Interfacial methods Static methods i=0 Potentiometry E dynamic methods i > 0 Conductometry G=1/R Conductometric titrations Potentiometric titrations volume Controlled potential Constant electrode potential coulometry Q = i dt Voltammetry I=f(E) bulk methods Amperometric titrations volume Electrogravimetry (wt) Constant current Coulometric titrations Q=it Electrogravimetry (wt) Some factors to be considered in the design of a voltammetric, or other electrochemical, study Goal − analytical? thermodynamic? kinetic? mechanistic? synthetic? Working electrode − material? shape? size? rotate? pretreatment? Ionic phase − solvent? analyte concentration? vary? product present? outgas? Other electrode − spacing? reference-reaction? junction? quasi-reference? Supporting electrolyte − none? excess? choice? vary? buffer? Excitation − potential or current? single? forward + reverse? repetitive? Applied waveform − step? ramp? pulse? square-wave? ac? combination? Time resolution − equilibrium? steady-state? transient? frequency domain? Ohmic polarization, Ru − ignore? compensate? measure-and-model? Activation polarization − reversible? quasireversible? irreversible? Concentration polarization, transport − diffusion? migration? convection? Homogeneous chemistry − absent? equilibrium? kinetics? ion-pairing? Predictive modelling − analytical? numerical? simulative? how simulate? Theory/experiment comparison − intuitive? overlay? data-processing? replot? o Voltammetry Purpose Voltammetry is used to study the mechanism, kinetics, and thermodynamics of chemical reactions. Voltammetry: measurement of current (I) as a function of applied potential (E). Different voltammetric techniques are distinguished primarily by the potential function that is applied to the working electrode and by the material used as the working electrode. Cyclic Voltammetry Purpose Cyclic Voltammetry is used to study the mechanism, kinetics, and thermodynamics of chemical reactions. Both heterogeneous reactions occurring at the electrode surface, and homogeneous reactions in solution can be studied. In the classical Cyclic Voltammetry triangle waveform, the potential is swept from an Initial E, to vertex E, and back to Final E, where Final E equals Initial E. An example of this applied waveform is shown below. Repeating this waveform for N times will perform N cycles of Cyclic Voltammetry. EXCITATION -2 Ev1 Ef 0 E i I (A) E (V) Ev1 10 -1 1 Ei Ef 0 -10 2 0 RESPONSE 20 Ev2 Ev2 20 40 60 t (s) 80 100 -20 1 0 -1 E /V (vs.SCE) -2 Cyclic Voltammetry For a simple redox reaction: R + ne O A: At the start of the experiment, the bulk solution contains only the reduced form of the redox couple (R) so that at potentials lower than the redox potential, i.e. the initial potential, there is no net conversion of R into O, the oxidised form (point A). C: At the anodic peak, the redox potential is sufficiently positive that any R that reaches the electrode surface is instantaneously oxidised to O. Therefore, the current now depends upon the rate of mass transfer to the electrode surface and so the current starts to decrease. 30 E 20 I / A B: As the redox potential is approached, there is a net anodic current which increases exponentially with potential. As R is converted into O, concentration gradients are set up for both R and O, and diffusion occurs down these concentration gradients. 10 D: 0Upon reversal of the scan, the current A continues to decay until the potential B -10 the redox potential. nears D -20 E: At this point, a net reduction of O to R -30 occurs which C causes a cathodic current which a peak 0.6 eventually 0.4 0.2 produces 0.0 -0.2 -0.4shaped + response. E / V vs. Ag /Ag A: initial state of the system is established. Cyclic Voltammetry If a redox system remains in equilibrium throughout the potential scan, the electrochemical reaction is said to be reversible. the following parameters characterize the cyclic voltammogram of the redox process. + Ep = (Ep,a – Ep,c) = 59/n mV at 25 oC for all scan rates Ip,a/Ip,c = 1 for all scan rates. the peak current function increases linearly as a function of the square root of v. + 30 20 I / A the peak width is equal to 28.5/n mV for all scan rates. -1 Fc/Fc couple recorded in DMSO/TBAP at 100 mVs scan rate vs. Ag/Ag reference electrode on Pt electrode + -1 Fc/Fc couple recorded in DCM/TBAP at 100 mVs scan rate vs. SCE reference electrode on Pt electrode 10 0 -10 -20 -30The peak current, i , is described by the p -40Randles-Sevcik equation for reversible redox -50reaction: -60I = (2.69x105) n3/2 A C D1/2 v1/2 p 1.0 0.5 0.0 E/V -0.5 Cyclic Voltammetry The potential difference between the reduction and oxidation peaks of a redox couple is theoretically 59 mV for a reversible reaction. In practice, the difference is typically 70-100 mV. 40 20 Larger differences, or nonsymmetric reduction and oxidation peaks are an indication of a nonreversible reaction. Ep, Ip,a/Ip,c and Ip vs. parameters of cyclic voltammograms make CV most suitable for characterization and mechanistic studies of redox reactions at electrodes. I / A 0 -20 -1 25 mVs -1 50 mVs -1 100 mVs -1 250 mVs -1 500 mVs -40 v1/2 To follow the change of the parameters; Ep, Ip,a/Ip,c and Ip vs. v1/2 ; CVs at diferrent scan rates are recorded. -60 0.6 0.4 0.2 0.0 -0.2 + E / V vs. Ag /Ag -0.4 -0.6 Mechanistic complications: The E mechanism Mechanistic complications: The EE mechanism Mechanistic complications: The EC mechanism The shape of a voltammogram can be significantly altered if there is a coupled chemical reaction either before or after the electrochemical process. Further complications attributed to the chemical nature of the reaction, the degree of reversibility, the rate and equilibrium constants of the process can all play a part in the final shape of the voltammogram and on the information that can be obtained from a set of experiments. In general terms, coupled mechanistic schemes are described by the letters E (electrochemical) and C (chemical). Mechanistic complications: The EC mechanism Mechanistic complications: The EC mechanism Mechanistic complications: The EC mechanism Mechanistic complications: The EC mechanism Mechanistic complications: The ECE’ mechanism Mechanistic complications: The ECE’ mechanism Mechanistic complications: The EECE’ mechanism Mechanistic complications: The EECE’ mechanism Mechanistic complications: The ECECE mechanism EE ECE Mechanistic complications: The ECECE mechanism ECEC ECEC The design of electrochemical cell Electrodes working electrode(s), counter electrode and reference electrode Electrolyte solvent and counter salt Cell container Gas purging Cyclic Voltammetry Working electrode most common is a small sphere, small disc or a short wire, but it could also be metal foil, a single crystal of metal or semiconductor or evaporated thin film has to have useful working potential range can be large or small – usually < 0.25 cm2 smooth with well defined geometry for even current and potential distribution mercury and amalgam electrodes reproducible homogeneous surface, large hydrogen overvoltage. wide range of solid materials – most common are “inert” solid electrodes like gold, platinum, glassy carbon. reproducible pretreatment procedure, proper mounting Counter electrodes to supply the current required by the W.E. without limiting the measured response. current should flow readily without the need for a large overpotential. products of the C.E. reaction should not interfere with the reaction being studied. it should have a large area compared to the W.E. and should ensure equipotentiality of the W.E. Reference electrode The role of the R.E. is to provide a fixed potential which does not vary during the experiment. A good R.E. should be able to maintain a constant potential even if a few microamps are passed through its surface. mercury – mercurous chloride (calomel) the most popular R.E. in aq. solutions; usually made up in saturated KCl solution (SCE); may require separate compartment if chloride ions must be kept out of W.E. silver – silver halide gives very stable potential; easy to prepare; may be used in non aqueous solutions Reference electrode A reference electrode is an oxidation–reduction half-cell of known and constant potential at a particular temperature. It consists of three parts: An internal element. A filling solution that also constitutes the salt-bridge electrolyte. An area in the tip of the electrode that permits a slow, controlled flow of filling solution to escape the electrode and maintain electrical conductance with the remainder of the electrochemical cell. The silver–silver chloride reference electrode The silver–silver chloride electrode is often a silver wire coated with silver chloride that is immersed in a filling solution of potassium chloride of known concentration, usually 1.0M, and saturated with silver chloride. In the cartridge form the metal is in contact with a paste of the salt moistened with electrolyte, and all is enclosed in an inner glass tube. One equilibrium involved is The expression for the electrode potential is In addition, there is a chemical equilibrium, Combining Eqs. gives the Nernst expression for the chloride ion: This simplifies to Calomel reference electrode Calomel electrodes have a construction that is similar to the cartridge type of silver–silver chloride electrodes. They comprise a platinum wire in contact with mercury and a paste of mercury( I) chloride, mercury, and potassium chloride, moistened with the filling solution, which is enclosed in an inner glass tube and makes contact with a filling solution of potassium chloride (usually 0.1M, 1.0M, or saturated, 4.2M) through a porous plug. The electrolyte solution it consists of solvent and a high concentration of an ionised salt and electroactive species studied. a high concentration of an ionised salt is used to diminish mass transport of the electroactive species by migration. to increase the conductivity of the solution, to reduce the resistance between W.E. and C.E. (to help maintain a uniform current and potential distribution) to reduce the resistance between W.E. and R.E. to minimize the potential error due to the uncompensated solution resistance iRu Solvent and Supporting Electrolyte Almost every electrochemical experiment is carried out in a medium consisting of a solvent and supporting electrolyte. A handful of solvent-electrolyte combinations would probably suffice for the majority of electrochemical applications. In order to optimize conditions for an electrode reaction, one must consider how its chemical and electrochemical features, for example, the chemical properties of expected intermediates, might be affected by the solvent or electrolyte. A solvent is chosen such that its merits outweigh its disadvantages in a particular situation. A good solvent system for one type of experiment may be wholly unsuitable for other applications. The most important properties that the ideal solvent system ought to possess are electrochemical inertness (stability over a wide range of potentials), high electrical conductivity, good solvent power, chemical inertness, liquid range, availability in pure form or ease of purification, and low cost. Solvent and Supporting Electrolyte Electrochemical Inertness The solvent system should not undergo any electrochemical reaction over a wide range of potentials from very positive (strongly oxidizing) to very negative (strongly reducing). The potential at which electrochemical reaction of the solvent system (either the supporting electrolyte or the solvent itself) commences is known variously as the solvent breakdown potential, solvent decomposition potential, or solvent window. Certain systems can be used over a very wide potential range; one of the best for this purpose is a solution of tetrabutyl ammonium hexafluorophosphate in acetonitrile, which exhibits anodic and cathodic breakdown limits of +3.4 and -2.9 V (vs. SCE), respectively. In practice, however, one rarely needs both extended positive and negative ranges in a single set of experiments; solvents are frequently used that exhibit either a very negative or very positive decomposition potential, but not both. Both nitrobenzene and methylene chloride have been used for studies of oxidation processes because they are hard to oxidize, hovewer they are quite easily reduced. Conversely, liquid ammonia and methylamine are good solvents for electrochemical reductions, although poor for oxidations. Solvent and Supporting Electrolyte Chemical Inertness The solvent should not react with the electroactive material nor with intermediates or products of the electrode reaction under investigation. No one solvent can reasonably be expected to be unreactive toward all of the many kinds of reactive species that can be generated electrochemically. When selecting a solvent, one does have to make some informed guesses about likely intermediates and products, based on chemical experience. The solvent and electrolyte can affect an electrode process in a number of ways other than by reacting chemically with the electrolysis intermediates or products. The rate of heterogeneous electron transfer from the electrode to the electroactive substance can be affected by the structure of the electrical double layer at the electrode surface, which in turn is dependent on the nature of the solvent and supporting electrolyte. Acidic cations, such as tri- ethylammonium and guanidinium ions, can protonate shortlived intermediates generated at the electrode surface before such intermediates can escape into bulk solution. Recomended Solvent and Supporting Electrolyte Electrochemistry of inorganic salts Solutions of inorganic salts in water meet many of the preceding desirable solvent criteria, and have been used for innumerable electrochemical studies. Much inorganic electrochemistry has been carried out in water with little difficulty. Many inorganic supporting electrolyte (e.g., NaBF4, LiC104, or NaCIO4) may be necessary in such cases. Electrochemistry of Organic and organometallic compounds Recommended electrolytes include tetrabutylammonium hexafluorophosphate (TBAHFP), tetrabutylammonium perchlorate (TBAP) and tetrafluoroborate (TBATFB), which are readily obtained in pure form and have high solubilities in AN, DMSO, DCM, THF and etc. Some tips to perform a CV measurements Chose a proper solvent and supporting electrolyte. Chose a proper electrode configuration. Prepare 0.1 M supporting electrolyte solution. Take 5 mL of supporting electrolyte solution into the CV cell Purge with an inert gas to remove desolved oxygen at least 15 min. Maintain an inert gas blanket during the experiment. Take the background CV of the supporting electrolyte system to ensure the purity and to determine the solvent window. If the background CV is clear; Dissolve electroactive species to optain a known concentration. Record the CV of the electroactive species with different scan rates, swithcing potential, electrode set, concentration etc. Differential Pulse Voltammetry Differential Pulse Voltammetry (DPV) is used for both quantitative chemical analysis and to study the mechanism, kinetics, and thermodynamics of chemical reactions. It is often used with a Dropping Mercury Electrode (DME) or with a Static Mercury Drop Electrode (SMDE). When used with either of these electrodes it is often called Differential Pulse Polarography (DPP), although this name is often used for the general technique. DPV used as an analytical tool offers advantages when compared to other electrochemical techniques. DPV is very sensitive – often allowing direct analyses at the ppb (parts per billion) level. When used in a stripping mode, ppt (parts per trillion) analyses are possible. DPV owes its sensitivity to the relatively short pulse time and its differential nature. The short pulse time increase the measured currents while the differential measurement discriminates against background processes. Differential Pulse Voltammetry -1.2 60 -1.0 40 20 -0.6 Data read point I / mA E / mV -0.8 -0.4 0 -0.2 -20 0.0 -40 0.2 -10 0 10 20 30 40 50 t /s 60 70 80 90 100 -60 110 0.0 -0.5 E / mV vs. SCE -1.0 -1.5 Differential Pulse Voltammetry 100 80 60 40 60 A -1 25 mVs -1 50 mVs -1 100 mVs -1 250 mVs -1 500 mVs 40 R2 R1 B R3 20 20 0 0 -20 O2 R1 O1 R3 R2 O'1 -20 -40 O1 O'1 -40 -60 -60 -80 1.5 1.0 0.5 0.0 -0.5 E / mV vs. SCE -1.0 -1.5 -2.0 1.5 1.0 0.5 0.0 -0.5 E / mV vs. SCE -1.0 -1.5 -2.0 Chronoamperometry The electroanalytical techniques, chronoamperometry, chronocoulometry, and chronoabsorptometry are all based on the same excitation function of one or more potential steps that are applied to an electrode immersed in a nonstirred solution. The system response is thus identical for all three techniques. They differ only in the data domain of the monitored response. Ev1 -0.5 0.1 0.0 I / mA -0.4 V / mV -0.3 -0.2 -0.1 0.0 Ei 0 -0.2 Ev2 5 10 15 t (ms) -0.1 -0.3 20 25 0.0 0.1 0.2 t/s 0.3 0.4 Chronoamperometry I Cottrell Equation: Ev1 -0.5 0.0 I / mA V / mV -0.3 -0.2 -0.1 0.0 Ei 0.0 Ev2 0.1 1/ 2 t 1/ 2 0.1 -0.4 nFACoO D1O/ 2 0.2 0.3 t (s) -0.1 -0.2 -0.3 0.4 0.5 0.0 0.1 0.2 t/s 0.3 0.4 Chronocoulometry Anson Equation: Ev1 -0.5 -0.4 V / mV -0.3 Q -0.2 -0.1 0.0 Ei Ev2 0.0 0.1 0.2 0.3 0.4 nFACoO D1O/ 2 1/ 2 0.5 t (s) Q A Forward scan B Forward scan 0 0 Backward scan t/s Backward scan t1/2 / s1/2 t 1/ 2 K t 1/ 2 Chronoamperometry Anson Equation: Q( t ) A Q/ mC nFACoO D1O/ 2 1/ 2 t 1/ 2 Q dl nFAO B Qt Forward scan Qdl Forward scan Qdl Qads 0 0 Backward scan t/s Backward scan t1/2 / s1/2 In-Situ SPECTROELECTROCHEMISTRY Potantiostat studying electrode processes by experiments that involve spectral changes with the usual electrochemical variables of current, charge, and potential. Spectrophotometer • • • • It is posible to measure: Absorbance Transmitance Reflectance Irradiance Light Source In situ techniques involve examination of the electrode surface due to the interaction of electromagnetic radiation while it is immersed in solvent in the electrochemical cell, often under potential control and during the passage of current. optically transparent thin-layer electrode (OTTLE) Quartz thin-layer spectroelectrochemical Cell configuration A -40 A R2 R1 B Abs. -20 0 -1 50 mVs -1 100 mVs -1 250 mVs -1 500 mVs 20 O1 40 60 1.5 O2 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -20 C -2.5 D B -10 0 O2 R1 O1 Abs. I / A I / A In-Situ SPECTROELECTROCHEMISTRY R2 10 20 300 30 1.5 1.0 0.5 0.0 -0.5 -1.0 -1.5 -2.0 -2.5 400 500 600 700 Wavelength (nm) 800 900 300 400 500 600 700 Wavelength (nm) E / V vs.SCE CVs (A) and DPVs (B) of MnPc on Pt working electrode versus SCE in DMSO/TBAP electrolyte system. In-situ UV-vis spectral changes of MnPc A) Eapp= -0.50 V. B) Eapp= -1.45 V. B) C) Eapp= 0.55 V. D) Eapp= 1.00 V. 800 900 Stripping Voltammetry Stripping voltammetry is a very sensitive method for the analysis of trace concentrations of electroactive species in solution. Detection limits for metal ions at subppb concentrations have been reported. In this experiment, a mercury working electrode is used – such as; the Hanging Mercury Drop Electrode (HMDE). Metal ions in solution are first reduced to metallic form and concentrated as mercury amalgam in a mercury film electrode. After concentration, they are re-oxidized into solution ("stripped") from the electrode. There are 3 important parts in a stripping experiment: Deposition Quiet time Stripping Stripping Voltammetry Stripping Voltammetry Deposition During the deposition step, the potential applied to the mercury electrode is held at a value (Deposition E) at which the ions are reduced to metal for a pre-determined time period (Deposition Time). The metal then amalgamates with the mercury electrode. The effect of this amalgamation is to concentrate the metal in the mercury electrode, and hence the concentration of metal in the electrode is much greater (typically 2 or 3 orders of magnitude) than the concentration of metal ion in the solution (consequently, the deposition step is often called the preconcentration or accumulation step). Quiet time The efficiency of the deposition can be increased by stirring either the solution or rotating the electrode. Stripping Voltammetry Stripping During the stripping step, the applied potential is scanned in a positive direction, and the metal in the mercury electrode is oxidized back to ions in solution; that is, the metal is "stripped" from the electrode. The potential at which the stripping occurs is related to the redox potential of the analyte, and hence the potential of the current peak on the stripping step can be used to identify the analyte. The magnitude of the current of the stripping peak is proportional to the concentration of the analyte in the mercury electrode. Since the concentration of the analyte in the electrode is related to its concentration in solution, the stripping peak current is therefore proportional to the solution concentration. For quantitative analysis, a series of standard solutions must also be run. This method is capable of quantitative measurements to the parts per billion range. A number of different wave forms have been used for the stripping step, including linear sweep voltammetry (LSSV), differential pulse voltammetry (DPSV), and square wave voltammetry (SWSV). SWSV and DPSV are more commonly used, due to their lower detection limits. Stripping Voltammetry anodic stripping voltammetry The above method is called anodic stripping voltammetry (ASV), since the stripping current is anodic. This method can be used for metal ions that can be readily reduced to the metallic state and reoxidized - about 20 metal ions, including lead, copper, cadmium, and zinc. This is not as many as can be detected using atomic absorption spectroscopy (AAS), although the sensitivity of ASV is comparable with, and sometimes better than AAS. The advantage of ASV over AAS is its ability to detect several metal ions simultaneously. In addition, different oxidation states of a given metal can be detected (e.g., arsenic and antimony). Stripping Voltammetry cathodic stripping voltammetry and adsorptive stripping voltammetry Other stripping voltammetric techniques include cathodic stripping voltammetry (CSV) and adsorptive stripping voltammetry (AdSV). The basis for CSV is the oxidation of mercury followed by the formation of an insoluble film of HgL (L is the analyte) on the surface of the mercury electrode during the deposition step. CSV is most commonly used for detection of sulfur-containing molecules (e.g., thiols, thioureas, and thioamides), but it has also been used for molecules such as riboflavin and nucleic acid bases (e.g., adenine and cytosine). AdSV is different from ASV and CSV in that the deposition step is nonelectrolytic, and occurs via the adsorption of molecules on the surface of the working electrode (the HMDE is most commonly used). The stripping step can be either anodic or cathodic. AdSV has been used for organic molecules (e.g., dopamine, chlorpromazine, erythromycin, dibutone, and ametryne) and for metal complexes of metals not amenable to detection by ASV (e.g., cobalt and nickel). Stripping Voltammetry Stripping Voltammetry Cd2+ and Cu2+ solution; Stripping Voltammetry Zn2+, Pb2+, Cd2+ and Cu2+ solution; Stripping Voltammetry What are the detection limits? With ASV, the measurement plating time is proportionate to the detection limit and, as such, longer plate times will increase the detection limit: Part per million is instantaneous Part per billion in 20 seconds or less Part per trillion takes 1-3 minutes What kind of sample preparation is required? In General: no electrode rotation or sample de-oxygenation is required. Clean samples: require no sample preparation other than the addition of a suitable supporting electrolyte. Stripping Voltammetry How accurate is ASV? Accuracy is proportionate to the way you calibrate your sample: 5% when calibrated directly via the method of standard additions. 10% when a calibration curve is built before measuring unknowns . 20% - 40% when operating uncalibrated. The sensitivity of voltammetric methods is due to the use of a pre- concentration, or accumulation, step in which the analyte is accumulated at the electrode by either a faradaic (anodic or cathodic stripping) or non-faradaic (absorptive) process. The analytical signal is then generated by the subsequent voltammetric stripping step, where the voltage is swept, or stepped, so as to remove the adsorbed analyte from the electrode. The current during this process is recorded, usually as a function of voltage, and the area of the current wave produced (proportional to the charge passed) is measured. Quantification is then performed by calibration, usually by a sequential standard addition methodology, where known quantities of a standard solution are added to the same analysis vessel. Stripping Voltammetry Effect of the deposition time upon DPV adsorptive stripping detection of 10 µM daunomycin in 200 mM acetate buffer at pH 5.0 on a HMDE; deposition potential -0.65 V, scan rate 10 mV/s, pulse amplitude 25 mV. Stripping Voltammetry Effect of the deposition time upon DPV adsorptive stripping detection of 10 µM daunomycin in 200 mM acetate buffer at pH 5.0 on a HMDE; deposition potential -0.65 V, scan rate 10 mV/s, pulse amplitude 25 mV. Stripping Voltammetry Effect of the deposition potential upon DPV adsorptive stripping detection. -0.90 - -1.40 V (a - f) Stripping Voltammetry Effect of the deposition time upon DPV adsorptive stripping detection 30, 60, 120, 180, 300 s Stripping Voltammetry